Jongia Mixing Technology

We understand your process

Jongia Mixing Technology has over 85 years of experience and therefor an extensive knowledge in the various process industries, knowing market specific trends, requirements and needs. With continuous innovation we ensure maximum process results. Being an innovative stirring & mixing equipment supplier, we earned a leading position over the years. Our high-quality mixers and agitators are exported all over the world. Global reach is supported locally through a wholly owned subsidiary in Germany, USA, China and a network of associated companies worldwide.

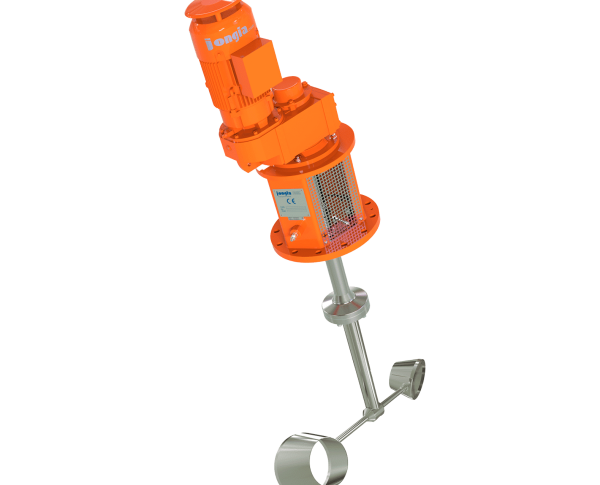

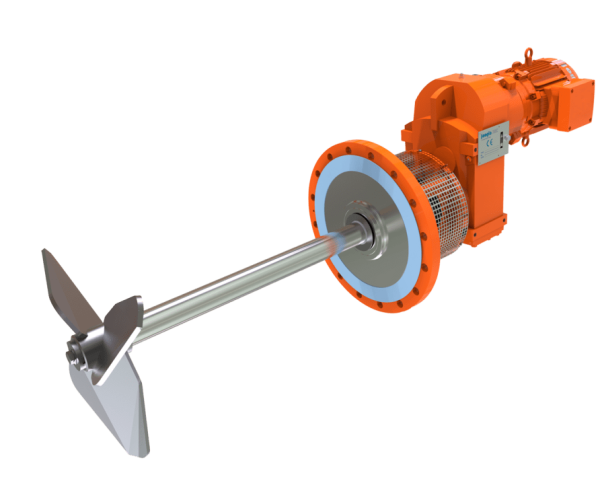

Agitators and Mixers

Jongia has a comprehensive range of stirring and mixing equipment and systems. We ensure the best possible solution for the given process, choosing from our wide range of mixers and agitators. We offer top, side and bottom entry, special designs like magnetic mixers, as well as dynamic and static in-line mixers and powder dissolving installations.

Latest News

Jongia Mixing Technology joins BeStart Startup & Scaleup Programme with Liquidz

We are proud to share that Jongia Mixing Technology has been selected to participate in the BeStart Startup & Scaleup Programme with our latest innovation project: Liquidz. Introducing Liquidz: Real-Time Intelligence Inside the Mixing Tank At Jongia, we specialize in developing advanced mixing solutions for the process industry. With Liquidz, we are taking the next step in innovation by integrating

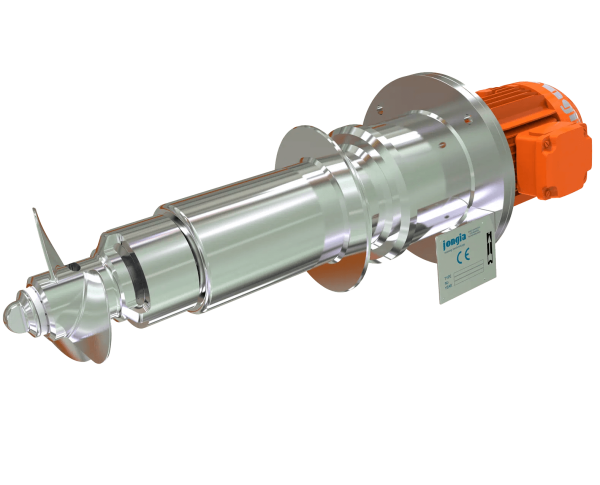

The Double Acting Axial Flow Turbine type AST-MTE mixing element

Operation of an AST-MTE Element Operation of an AST-MTE Element This element can be used in both CW (clockwise) and CCW (counterclockwise) directions. In one case, the inner AST element is downward-pumping with the outer tips pumping upward, and in the other case, it’s the opposite.This element is highly effective when dealing with a viscous fluid (often with higher density)

Jongia Mixing Technology Agitators in Process Installations

This reactor setup from Veenbrink RVS, equipped with Jongia agitators, forms the foundation for polymer production. The system is applied in an ATEX classified zone: the equipment zone 1 IIB T2, whilst the space itself is designated as zone 2 IIB T2. Furthermore, the reactor setup meets the highest hygienic requirements. Mixing technology for highly viscous media up to 200,000

Frequently Asked Questions

What is Jongia Mixing Technology known for?

Jongia Mixing Technology is known for its over 85 years of experience in providing stirring and mixing equipment across various process industries. Our knowledge of market-specific trends ensures continuous innovation and maximum process results.

What industries does Jongia serve?

Jongia serves several industries, including Food & Beverages, Dairy, (Petro)Chemical, Bio-based & Environmental, Energy, and Pharma & Personal Care, showcasing our versatility in mixing technology applications.

What types of products does Jongia offer?

Jongia offers a comprehensive range of mixing equipment including top, side, and bottom entry agitators, magnetic mixers, as well as dynamic and static in-line mixers, and powder dissolving installations.

Is Jongia a global company?

Yes, Jongia has a global reach, exporting its high-quality mixers and agitators worldwide and maintaining local support through subsidiaries in Germany, USA, China, and a network of associated companies.

How does Jongia ensure product quality?

Jongia ensures product quality by continuously innovating its mixing technology, having extensive industry expertise, and providing tailored solutions to meet specific process requirements across various sectors.

Stay informed

Sign up for our newsletter and receive the latest news