After Sales

Flexible and multifunctional

Process installations are often in continuous operation and are used to produce a wider variety of products. Therefore, new mixing equipment must be multifunctional and is subject to more demanding requirements. Guarantee/warranty conditions are also becoming increasingly strict. How does Jongia meet those (changing) requirements? Jongia offers the type of high-quality service that customers ask for with regard to Total Cost of Ownership (TCO) and Total Productive Maintenance (TPM) strategies. Service and maintenance are an integrated part of our stirring and mixing concepts. We have experienced and qualified service engineers available and guarantee swift reaction times.

Service contracts

Our service contracts are tailor-made to meet the requirements for preventive maintenance of your mixers. Our expert engineers will analyze your specific needs and offer you a maintenance plan as well as training services to instruct your personnel on maintenance and how to obtain maximum effectiveness from your mixers.

Frequently Asked Questions

What types of services does Jongia offer after installation?

Jongia provides various services including maintenance, spare parts supply, rental units, and process optimization. Our services ensure the longevity and efficiency of your mixing equipment, addressing any issues that may arise and improving overall performance.

How can I customize my maintenance plan?

Jongia offers tailor-made service contracts that are designed to meet your specific preventive maintenance requirements. Their expert engineers will analyze your needs and create a personalized plan that includes training for your personnel on proper maintenance practices.

Are spare parts readily available?

Yes, Jongia has spare parts often available from stock, machined in-house or sourced from reputable sub-suppliers. Our dedicated spares sales engineers are prepared to provide quick assistance to ensure minimal downtime for your equipment.

What support is offered during installation?

Jongia provides worldwide support during the installation and commissioning of your production equipment. Our experts ensure proper installation and functioning, which helps achieve optimal process results and enhances equipment durability.

How can I access 24/7 service?

Jongia has a global service network in collaboration with the HEINKEL Drying and Separation Group, ensuring 24/7 service availability. Our technicians are ready to help resolve issues quickly, reducing downtime and keeping your production running smoothly.

Maintenance

An agitator is the heart of your installation and should be running smoothly at all times. Our specialists will carry out the prescribed maintenance and ensure safe and durable operation providing you with continuity of production.

Spare Parts & Repairs

Spares machined in-house by our experienced operators or from well-reputed sub-suppliers are often available from stock or with the shortest possible delivery times. Our dedicated spares sales engineers are ready to assist you.

Installation & Commissioning

Our experts support you worldwide during installation and commissioning of your production equipment. Our support ensures proper installation and functioning of our equipment guaranteeing optimal process results and durability.

Download our VCA certificate here.

Service 24/7

Our worldwide service network, in cooperation with the HEINKEL Drying and Separation Group, is available to you 24/7. Our technicians help you solve problems fast and efficiently, so that your production can be up and running again quickly.

Rental units

We offer a rental equipment programme which enables process engineers to optimize a process before committing to a large capital purchase. Our process engineers are available to support you during testing with their expert advice.

Process Optimisation

After commissioning, we will support you in the optimization of your process making sure our equipment functions to your satisfaction. Extensive tests provide information on the functionality and efficiency of the agitators in your production process.

We assist you during from inquiry to installation & commissioning and provide 24/7 after-sales services

Stay informed

Sign up for our newsletter and receive the latest news

After Sales Posts

The introduction of: Manager Service After Sales Thonnis de Jonge

Jongia Mixing Technology holds a good many professionals to its name. Every four weeks, we will introduce one of those professionals to you. This week, the honors go to Thonnis de Jonge. He made his start in 1999 as Service

The introduction of: Service Aftersales employee Frank van den Hoed

Jongia Mixing Technology holds a good many professionals to its name. Every four weeks, we will introduce one of those professionals to you. This week, we’d like to introduce the 65-year-old Amsterdam-born Frank van den Hoed. Frank has been working

Other Recent Posts

Jongia converts existing digester with unique stirring concept

Aben Green Energy awarded Jongia Mixing Technology the contract to produce 13 of its unique top-entry mixing devices supply. The agitators are destined for a biomass project. This is the second project for which Aben has contracted Jongia. Previously, special agitators were

High-Speed Disperser Technology: The Engineering Behind Effective Mixing

A Technical Guide by Jongia Mixing Technology Core Function High-speed dispersers excel at three critical tasks: Fracturing powder agglomerates into fine particles Creating uniform powder distribution throughout liquid mediums Facilitating complete dissolution of soluble materials Operating Principles High-speed dispersers transform

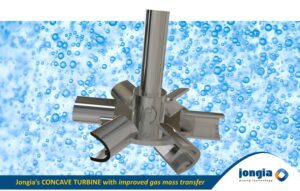

Concave Turbine with improved stability and performance

Concave turbines are often called “the next generation” turbines as they significantly perform better compared to conventional “Rushton” turbines. However, in most all engineering books and studies, the one and only turbine in which is referred to, is the Rushton