LiquidZ Sensor Technology

LiquidZ Sensor Technology

How the DNA of Mixing can ensure insight into the sludge treatment process.

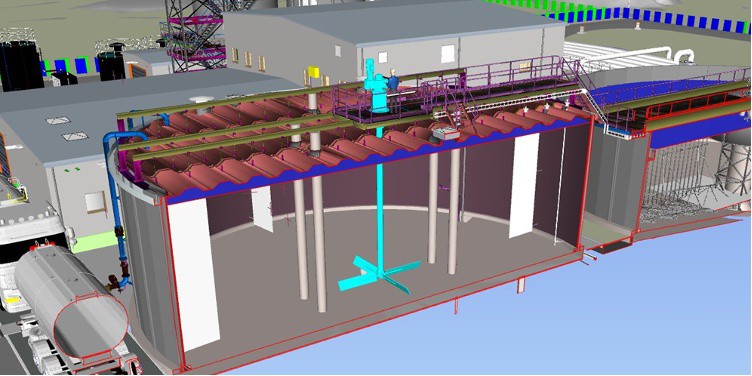

Jongia Mixing Technology and GMB have jointly started a project at the RWZI in Utrecht (Hoogheemraadschap de Stichtse Rijnlanden – HDSR) that uses sensors to measure the mixer on the external sludge buffer.

HDSR, in cooperation with the Consortium de Stichtse Kraan (Heijmans – GMB), has the management of the complete treatment plant, which therefore has to take care of the operation and maintenance of this plant.

As a result, several new developments are taking place at this treatment plant and GMB has given Jongia Mixing Technology the opportunity to monitor and optimize its own mixer.

In 2019, Jongia Mixing Technology started the project called “LiquidZ” in which the DNA of Mixing is realized through Sensor Technology. In short, it comes down to using sensors, complex data analysis and sound mixing expertise to gain insight not only into the mixing process in itself but also into the optimization opportunities on the process side of the customer.

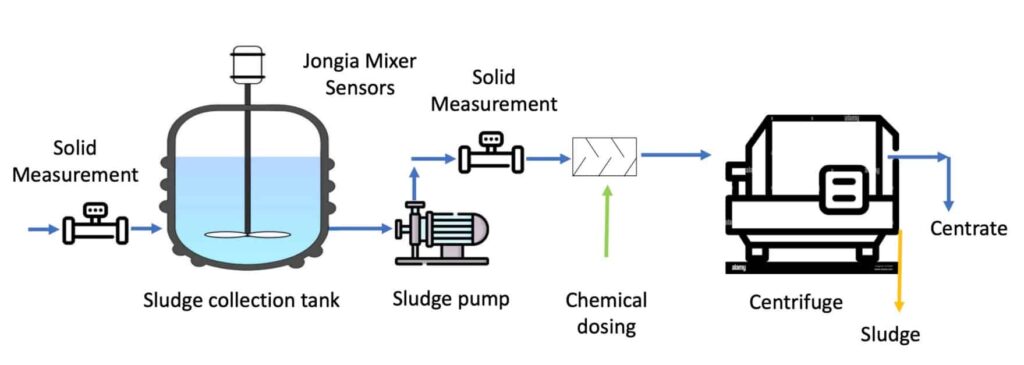

Since mid 2022, Jongia Mixing Technology, under the name LiquidZ, has mounted a sensor on the external Jongia sludge buffer mixer to retrieve and analyze mixing data. This sensor is directly connected to the mixer drive, but not only gives information about the mixer but also about the composition of the medium being mixed.

The sludge tank is fed from cargo loads transporting sludge from the region to the buffer tank. This can result in a varying composition of sludge which needs to be stirred by the Jongia mixer into a homogeneous product where the composition should be as constant as possible. The centrifuges processing the external sludge benefit from a sludge feed as constant as possible in volume and composition. When especially the parameter dry matter content of the supplied sludge varies, this results in a less efficient PE dosage and less efficient dewatering of the centrifuge.

The combination of data measured by Jongia and supplied by GMB is key to optimizing such a process.

Mixing sensors give a performance of the mixer in combination with the sludge buffer, which in turn are related to the dry matter output and centrifuge performance. Thus, sensor data, mixing knowledge, process knowledge and data analysis are combined for optimization of the sludge dewatering process.

Jongia and GMB have been able to demonstrate through testing that changes in mixing parameters have a direct relation to sludge processing in the centrifuge. And this opens the way for further optimization and cost savings.

In the coming period, LiquidZ will conduct further tests in cooperation with GMB, and it is expected that significant savings on sludge dewatering will become a reality.

Liquidz consists not only of the hardware of sensors on the agitator or in the tank, but especially the knowledge to correctly interpret the data in cooperation with the customer and convert it into a process improvement. That is what the DNA of Mixing is all about.

Let Jongia Mixing Technology optimize your process plant too! Feel free to contact the LiquidZ team.

What is LiquidZ ?

What is LiquidZ ? What is LiquidZ ? Explanation video What is LiquidZ? Jongia Mixing Technology has created an innovation team which is called ‘LiquidZ’. This team combines state of the Art Sensor Technology with data science and mixing technology.

LiquidZ Sensor Technology

LiquidZ Sensor Technology LiquidZ Sensor Technology Combining Sensor Technology with data science, Jongia has discovered the DNA of Mixing Technology. This allows Jongia to introduce The Smart Agitator! Jongia Mixing Technology has initiated a project which is called “LiquidZ” to

Frequently Asked Questions

What is LiquidZ?

LiquidZ is a project initiated by Jongia Mixing Technology and GMB that implements sensor technology to monitor and optimize mixing processes in sludge treatment. It aims to provide insight into mixing efficiency and optimization opportunities through data analysis.

How does the sensor technology work?

The sensors are mounted on the external Jongia sludge buffer mixer, providing real-time data on mixing parameters and the composition of the medium. This information is analyzed to improve mixing processes and enhance operational efficiency.

What benefits does LiquidZ offer?

LiquidZ helps achieve a more homogeneous sludge product, ensuring a consistent composition. It enhances the efficiency of centrifuges by optimizing the sludge feed, which leads to better dewatering and process performance.

How is the data from sensors utilized?

The data collected from sensors is analyzed alongside other parameters to correlate mixing performance with sludge processing. This analysis aids in process optimization and identifies potential cost savings in sludge treatment.

Who can benefit from the LiquidZ technology?

Any treatment plant involved in sludge processing can benefit from LiquidZ technology. Jongia Mixing Technology invites facilities to contact our team for tailored optimization solutions in their mixing and dewatering processes.

Contact our specialized team for all your questions

Tom Pruymboom

Sales Director

Area Worldwide