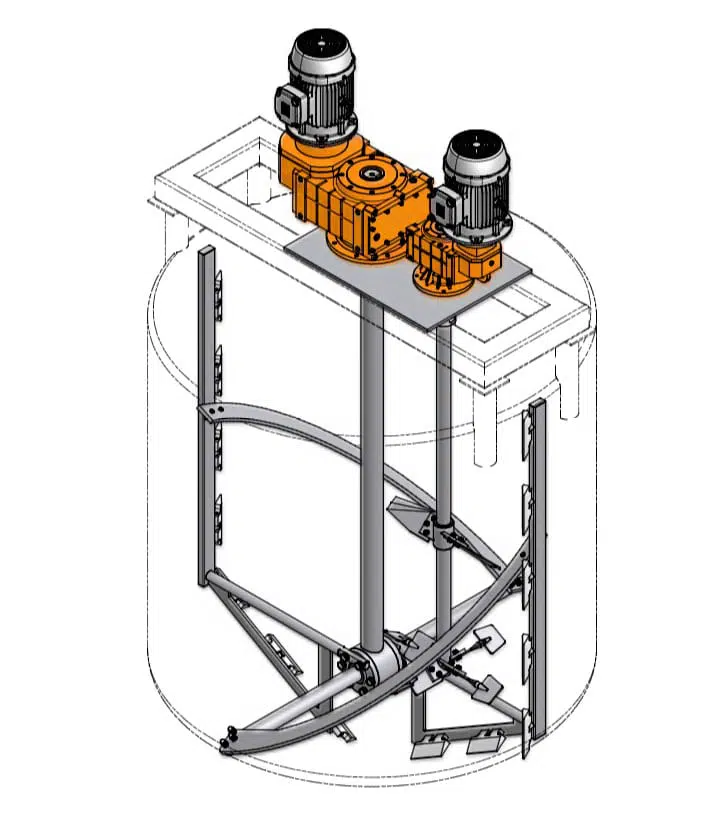

Counter rotating mixer

Types: CRM Mixer, Dual Mixing System

A combined process? Jongia’s combination mixers (type CRM or dual mixing system) are ideal in a process that requires the mixer to perform more than one specific duty.

Depending on the requirements, a vessel can be fitted with two or more separate mixers. A wide range of combinations is possible. A commonly used solution is an anchor type mixer with an axial flow type, a dispersion disc or a propeller type mixer.

In case the size of the vessel’s top limits the use of separate mixers, combination systems with a special hollow shaft construction are recommended. Being built on top of each other, with one mixer shaft passing through the other, each mixer shaft is separately driven. Our counter-rotating mixer (CRM) is fitted with such a construction.

CRM mixer

When your product is highly viscous our counter-rotating mixing system is the perfect substitute for the dual mixing system, because its working area is larger. An added advantage is that the system can be used when there is limited space on the tank top. JONGIA’s anchor mixer can be fitted with wall-contoured scrapers to ensure the best possible axial pumping action for products with a high solids content. When a more gentle product treatment is required, we recommend a parabolic anchor. A single or double 4-bladed axialflow/ multi counter-flow element of our own special design creates the necessary shear forces to mix liquids with low viscosities into high-viscosity products. The combi-system ensures perfect homogeneity.

Applications CRM Mixer

Dual Mixing System

To create a lump-free, homogeneous and stable product in the premix phase JONGIA offers its dual mixing system consisting of an anchor type mixer combined with a fast running dissolver for mixing in additives. The anchor mixer keeps the mixture homogeneous and is fed by the fast running mixer. JONGIA’s anchor mixer can be fitted with wall-contoured scrapers to ensure the best possible axial pumping action for products with a high solids content such as mural paints. When a more gentle product treatment is required, we recommend a parabolic anchor. A single or double 4-bladed axial- flow/multi counter-flow element of our own special design creates the necessary shear forces to mix liquids with low viscosities into high-viscosity products of up to 20.000 cP. The combi-system ensures perfect homogeneity.

Applications Dual Mixing System

Counter Rotating Mixing Element

Jongia Counter Rotating Mixing Element

Jongia’s counter-rotating agitator type CRM is a type of mixing device used in various applications.

The function of this type of mixer is to blend, homogenize, or emulsify liquids or powders.

The unique and most important aspect of a counter-rotating agitator is that it consists of two or more stirring elements that rotate in opposite directions. It’s essentially two agitators in one device.

Frequently Asked Questions

What types of mixers does Jongia offer?

Jongia offers two types of mixers: the CRM Mixer and the Dual Mixing System. These combination mixers are ideal for processes requiring more than one specific duty, allowing for versatile applications depending on the specific requirements of the mixture.

What is the advantage of the counter-rotating mixer?

The counter-rotating mixer (CRM) provides a larger working area compared to dual mixing systems, making it suitable for highly viscous products and limited space scenarios. It ensures effective mixing while maintaining product integrity, particularly for products with high solids content.

How does the dual mixing system work?

Jongia’s dual mixing system consists of an anchor type mixer and a fast-running dissolver, efficiently mixing additives to create a homogeneous product. The anchor mixer keeps the mixture consistent and can be tailored for high solid contents, ensuring optimal results.

What applications are suitable for the CRM mixer?

The CRM mixer is versatile and can be used in various applications, particularly in the food and chemical industries. It is designed for blending, homogenizing, and emulsifying both liquids and powders, making it suitable for many manufacturing processes.

How do the mixers handle different viscosities?

Jongia’s mixers cater to different viscosities, utilizing specialized designs such as wall-contoured scrapers for high solids products. The CRM mixer utilizes various blade types, allowing for gentle treatment of low-viscosity liquids while effectively mixing high-viscosity products.

Related Posts

The Counterflow: from request to solution

Mainly in the chemical industry, the Counterflow mixing element is applied in mixing processes of products such as paint, polymers, biodegradable plastics where starch is the basic component and medium viscous liquids. However, what kind of questions do the customers

The Counterflow: the top entry mixer for the chemical industry

The Counterflow mixing element doesn’t only move the liquid in the middle or on the outside of the tank, but both sides, in opposite directions. Jongia Mixing Technology has the Counterflow in its range, mainly for the chemical industry. The

Tutorial: How does the Gas Inducing Mixer work?

Jongia Mixing Technology designed the Gas Inducing Mixer to dissolve gas in liquid in order to achieve a (chemical/biochemical) reaction. The mixer is most commonly used in hydrogenation (curing) processes and especially for hydrogenation of fats (acids) in the food

Contact our specialized team for all your questions

Tom Pruymboom

Sales Director

Area Worldwide

Bart Brouwer

Area Sales Manager

Area Worldwide

Technical Questions?