Mixing Machines

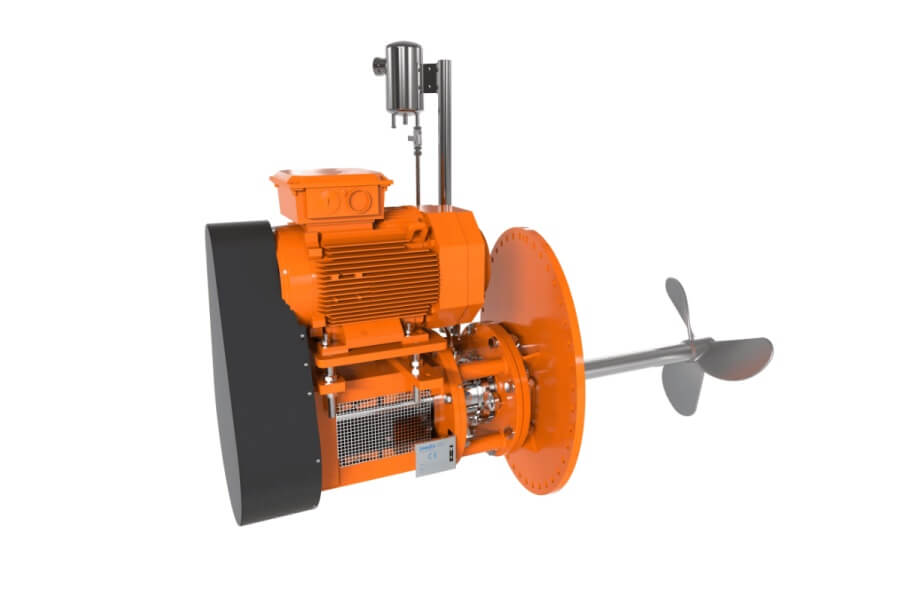

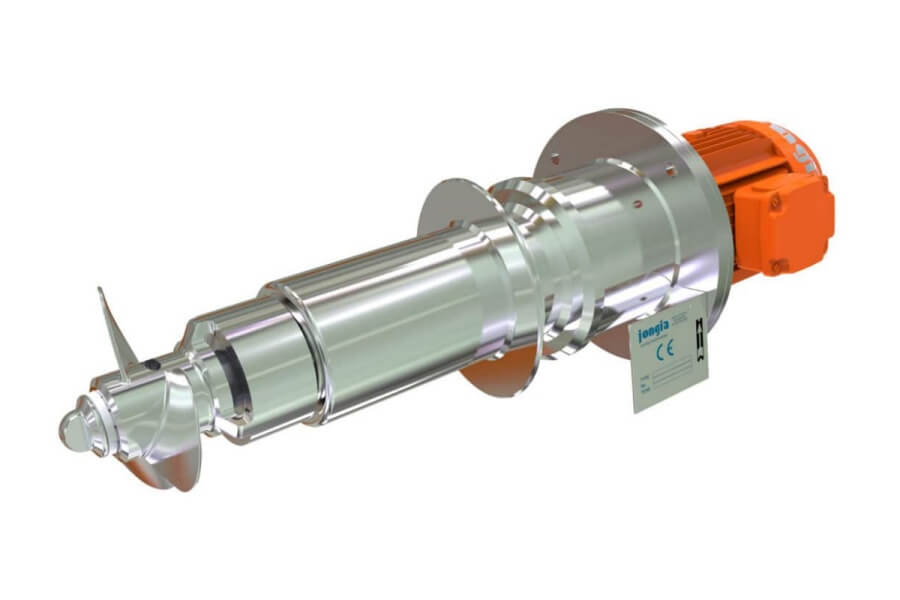

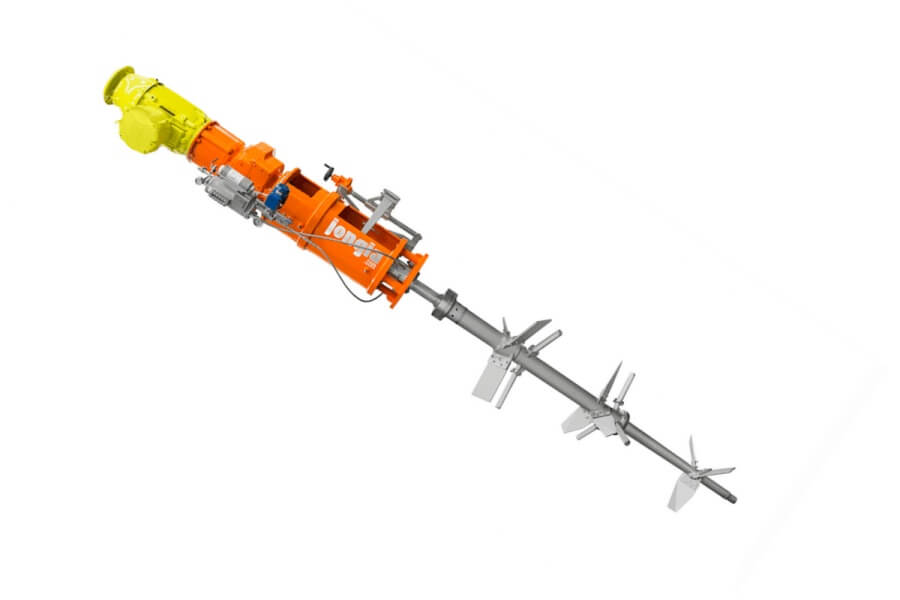

Jongia has a thorough range of mixing and also stirring tools, products and also systems. We guarantee the most effective possible remedy for the given process, picking from our vast array of agitators as well as mixing machines. We provide leading, side and also lower entrance agitators, special styles like magnetic mixing machines, in addition to vibrant and static in-line mixing machines and powder dissolving setups. Qualities of our blending devices and items are: Premium quality, Durability, Eco-friendly, Low maintenance. Relying on the application we separated our top, side and also lower entry mixing machines kinds into 3 levels: light, medium and heavy-duty.

Top-Entry Mixing Machines

Top-Entry mixing machines are a beneficial and inexpensive solution to mix components. Intended to achieve an even mixture without any contamination, they are employed in numerous industries such as food production, pharmaceuticals, and cosmetics. Featuring a top-mounted agitator that turns speedily to guarantee complete blending of the ingredients, these machines can be customized with different blades and attachments according to certain requirements. Furthermore, they possess enhanced safety features including overload protection and emergency stop buttons for improved safety.

Side-Entry Mixing Machines

Side-entry mixing machines make a perfect selection for companies searching to swiftly and efficiently blend components. These equipment have a side-mounted agitator that operates at high speeds to guarantee a thorough blending of elements. They are utilized in various fields such as food production, pharmaceuticals, and cosmetics, and can be altered with various cutting edges and attachments depending on the required result. Furthermore, they come supplied with security features such as overload protection and emergency stop buttons for additional protection. With their low-priced design and dependable functioning, side-entry mixing machines represent a superb selection for any business.

Bottom-Entry Mixing Machines

Companies looking to rapidly and effectively mix elements can find the ideal answer in bottom-entry blending machines. These feature bottom-mounted stirrers that operate at high speeds for a complete mix of constituents. From food production to pharmaceuticals and cosmetics, these machines are utilized in numerous industries and can be modified with various cutting edges or attachments depending on the outcome desired. Further, they are built with protective features such as overload protection and an emergency stop switch for extra security. With a cost-effective design and dependable operation, bottom-entry mixing machines offer a great choice for any business.

Efficient and dependable blending solutions can be provided by various types of industrial mixing machines, such as magnetic mixers, gas-inducing mixers, inline mixers, counter rotating mixers and conical helix mixers. Magnetic mixes create strong stirring force with the use of powerful magnets while gas inducing mixes use compressed air or gas to induce turbulence in the blend. Inline mixers have stationary shafts with blades that rotate within the tank and are designed for continuously operation and production. Counter rotating machines feature two separate shafts turning in opposite directions for full blending. Conical helix mixers have cone blade resulting in a helical flow pattern that increases efficiency. Whatever type you choose, all these special industrial agitators will offer exceptional performance and trustworthiness for any need.

Mixing Machines used in many industries

Such as: Production of chemicals, Manufacturing of paints and coatings, Manufacturing of textiles, Manufacturing plastic products, Metalworking and production, Ceramics, Glassmaking, Papermaking, Food and drinks, Pharmaceuticals, Cosmetic production, Cold and Hot brewing and distilling, water treatment, Petrochemical processing and Energy production. Let’s point out 3 huge production industries to help you understand how high quality mixing machines are used in those industries.

Food production Industry

In food production, the mixing of ingredients is pivotal and therefore mixers are required for said process. The side-entry and bottom-entry varieties of this machinery are commonly preferred due to their cost and dependability. High velocity agitators within these machines guarantee that elements are combined completely, with additional safety measures like overload protection and emergency shutoff buttons as supplementary protection. Blendings performed by magnetic mixers, gas-inducing mixers, inline mixers, counter rotating mixers and conical helix mixers can all be utilized in food production providing not only proficiency but also reliability.

Pharmaceutical industry

Pharmaceutical companies require accurate combos of ingredients to manufacture drugs and other goods, making mixing machines an absolute necessity. Cost efficiency and reliability make bottom-entry mixing machines a popular choice, and they come complete with high speed agitators that guarantee total mix of components. Moreover, added safety measures like emergency shutoff buttons and overload protection give added peace of mind. Pharmaceutical production can further make use of magnetic mixers, gas-inducing mixers, inline mixers, counter rotating mixers or conical helix mixers for reliable blending options at all times.

Textile Production Industry

The textile production industry requires mixing machines to combine numerous materials and materials. Due to their reliability and affordability, side-entry and bottom-entry mixers are popular picks. These machines boast high velocity agitators that guarantee blended components, plus extra safety aspects such as overload protection and emergency shut off buttons. In the textile production industry, efficient blending results that guarantee dependability can be achieved through gas-inducing mixers, inline mixers, magnetic mixers, counter rotating mixers and conical helix mixers.

Frequently Asked Questions

What types of mixing machines does Jongia offer?

Jongia provides a comprehensive range of mixing machines including top-entry, side-entry, and bottom-entry agitators. Additionally, we offer specialized designs like magnetic mixers, gas-inducing mixers, inline mixers, counter rotating mixers, and conical helix mixers for varied industrial applications.

Are Jongia's mixing machines customizable?

Yes, Jongia’s mixing machines can be customized with different blades and attachments based on specific processing requirements, allowing for tailored solutions for various industries.

What are the key features of Jongia's mixing machines?

Jongia’s mixing machines are known for their high quality, durability, eco-friendliness, and low maintenance. They also come equipped with safety features such as overload protection and emergency stop buttons.

In which industries are Jongia’s mixing machines commonly used?

Jongia’s mixing machines are utilized in multiple industries including food production, pharmaceuticals, textiles, chemical manufacturing, coatings, glassmaking, and more, providing efficient blending solutions.

What distinguishes the types of mixing machines offered?

The mixing machines are categorized into light, medium, and heavy-duty based on application, ensuring a suitable choice for varying operational needs while maintaining reliable performance.