Beverages

It is safe to say that mixing is a key technique in the beverage industry; it is hard to find a drink that doesn’t require any stirring or mixing.

As with the food industry in general, efficient production methods as well as top-notch hygienic standards play a major role. Additionally ATEX zoning can become a crucial issue when dealing with alcoholic beverages. Jongia is one of a select group of mixer manufacturers whose quality management system is approved for ATEX and IECEx by the prestigious DEKRA institute (explosion protection).

We’ve supplied our mixers to all the major players in the alcoholic as well as the non-alcoholic beverage industry.

For the best mixing solution we rely on our process knowledge of more than 85 years and our high quality sanitary design

Our innovative side entry magnetic driven mixer, the Magitator, is very suitable for the Beverage industry due to its sealless design. Hermetically tight vessels promote hygiene and since there is no seal the risk of contamination is eliminated.

Applications

Fruit Juices & Concentrates

Vegetable juices & concentrates

Flavored water

Ice cream

Energy drinks

Beer

Spirits

Coffee & Tea

Frequently Asked Questions

What is the key technique in the beverage industry?

Mixing is a fundamental technique in the beverage industry. It’s essential for creating a wide variety of drinks, ensuring ingredients are well incorporated. Proper mixing techniques enhance flavor and texture, making a drink appealing to consumers.

What role does hygienic standard play in beverage production?

Hygienic standards are crucial in beverage production to prevent contamination and ensure product safety. Companies must adhere to strict sanitation practices during production to maintain quality and protect consumer health. Efficient methods combined with hygiene enhance the overall quality of the final product.

Why is ATEX zoning important for alcoholic beverages?

ATEX zoning is important in the production of alcoholic beverages due to the potential for explosive environments. Proper management and equipment that comply with ATEX regulations ensure safety in facilities where flammable substances are present, thus protecting workers and assets.

What is the Magitator?

The Magitator is an innovative, side-entry mixer designed specifically for the beverage industry. Its sealless design allows for hermetically sealed vessels, promoting hygiene and eliminating the risk of contamination. This makes it ideal for handling various liquid products safely.

Who are the customers for Jongia's mixers?

Jongia supplies mixers to major players in both the alcoholic and non-alcoholic beverage industries. Our products are utilized across a variety of applications, including fruit juices, flavored water, and energy drinks, ensuring they meet the diverse needs of the market.

Contact our specialized team for all your questions

Tom Pruymboom

Sales Director

Area Worldwide

Bart Brouwer

Area Sales Manager

Area Worldwide

Other Food Industries

DAIRY

FOOD

Related Articles

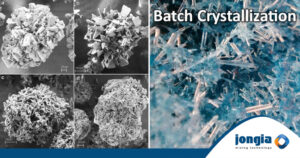

The introduction of crystallization in the mixing process for the dairy industry

Jongia Mixing Technology has initiated numerous mixing processes all over the world using her agitators. In some of these mixing processes, crystallization was a key factor in acquiring the desired final product. The process of crystallization is well-known in the

The Jongia Magitator: A multi-purpose magnetic agitator

To keep dairy or starch products homogeneous, the Jongia Mixing Technology Magitator, a magnet-driven agitator, is the right choice. In addition, this agitator maintains vegetable oil or juices at the right temperature. USP’s of the Magitator Opting for the Magitator

Jongia propellers are a valuable addition to the mixing process

Product friendly propellers are an indispensable part of our customers’ mixing process. Especially in the dairy industry, where slightly viscous liquids are mixed, it is very important that the products are not damaged during the mixing process. Jongia has unique