Biopolymers

What are biopolymers?

Biopolymers are polymers produced from natural sources. Natural polymers can be chemically synthesized from biological materials or biosynthesized by living organisms.

They consist of monomeric units bound together by covalent bonds. These monomeric units form larger molecules. Since biopolymers are derived from living organisms such as plants and microbes, they are a renewable resource that possess biodegradability.

In general, biopolymers are highly biodegradable. Because of this, they are also used in various sectors. Sectors that have an interest in the production of biopolymers include the food and biomedical industries. Biopolymers are promising materials because of their characteristics. Such as abundance in raw materials, biocompatibility and unique properties such as non-toxicity. With some nanoscale enhancements to improve their properties and practical applications, biopolymers are being explored in more and more possible ways.

Examples of biopolymers include proteins, starch, cellulose, DNA, RNA, lipids, collagen and carbohydrates.

We aim for maximum performance at lowest TCO

The market development of biopolymers

The global biopolymers market was valued at USD 13.7 billion in 2021 and is expected to reach about USD 35.25 billion by 2030. Europe is important for the majority of the revenue, at around 43.5% in 2021.

Types of biopolymer

Biopolymers can be classified according to different scales. These classifications are based on their origin, a number of monomeric units, on degradability, their heat resistance, etc. Some of the classifications are:

- Sugar-based polymers.

Starch or sucrose is used as a raw material for production. Lactic acid polymers are made using lactose from potatoes, corn, etc. - Starch-based polymers

Starch is a natural polymer composed of glucose. It is found in plant tissues. - Cellulose-based biopolymers.

Used for packaging, this polymer consists of glucose obtained from natural sources such as cotton. E.g. cellophane. - Synthetic materials

Degradable polymers can be made from synthetic materials obtained from petroleum.

Frequently Asked Questions

What are biopolymers?

Biopolymers are polymers from natural sources, either synthesized or biosynthesized by living organisms. They consist of monomeric units linked by covalent bonds and are highly biodegradable, used in sectors like food and biomedical due to their renewable nature and unique properties such as non-toxicity.

What is the current market value of biopolymers?

In 2021, the global biopolymers market was valued at approximately USD 13.7 billion. It is expected to grow significantly, reaching about USD 35.25 billion by 2030, indicating a strong demand for biopolymers globally.

What are some examples of biopolymers?

Examples of biopolymers include proteins, starch, cellulose, DNA, RNA, lipids, collagen, and carbohydrates. These substances are abundant in nature and offer diverse applications across multiple industries.

How are biopolymers classified?

Biopolymers can be classified based on their origin, number of monomeric units, degradability, and heat resistance. There are different categories such as sugar-based, starch-based, cellulose-based biopolymers, and synthetic materials.

What industries are interested in biopolymers?

Industries such as food, biomedical, and packaging have a keen interest in biopolymers. Their biodegradability and non-toxic nature make them suitable for applications that prioritize sustainability and environmental impact.

Bio-Based Industry Contacts

Tom Pruymboom

Sales Director

Area Worldwide

Jan Siert Tjeerdsma

Project manager

Technical Specialist

Bio-based & Environmental – Related Articles

Artificial Intelligence and Machine Learning are Moving Up into Mixing Technology

In the ever-evolving landscape of industrial technology, artificial intelligence (AI) and machine learning (ML) are making significant strides in various sectors, including mixing technology. Jongia Mixing Technology is at the forefront of this revolution, integrating state-of-the-art sensor technology with advanced

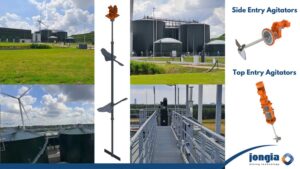

Jongia Mixing Technology‘s Biogas Production program

Optimizing Biogas Production with Jongia’s Innovative Technology Jongia is leading the way in improving biogas production with its advanced mixing solutions. In the biogas industry, effective mixing is key to maximizing energy output, minimizing power consumption and optimizing system efficiency.

VVTI Biogas Tilburg

VTTI Biogas Tilburg is developing a new bio-energy facility, focusing on processing organic waste. The plant is expected to produce approximately 23 million cubic metres of biogas annually. A portion of this will be converted into green gas for the