Waste water treatment

Wastewater treatments involve the treatment of wastewater. This is often the wastewater from households, businesses and often the rainwater from road pavements that is discharged through the sewer system.

We aim for maximum performance at lowest TCO

What is wastewater treatment?

In biological wastewater treatment, wastes are filtered out of the water by separating various bacteria. In physical chemical wastewater treatment, it is done by adding chemistry. There are two types of wastes: organic and chemical wastes. Examples of organic wastes are garden waste, leaves, food scraps and so on. Chemical wastes have non-natural origins, such as manufactured substances.

If the chemical waste cannot be purified in the water, it can cause problems to nature. This is because nature cannot break down these substances in the foreseeable future.

How does wastewater treatment work?

Wastewater can be released in a continuous stream or in batches. Depending on this, wastewater treatment or wastewater treatment must be tailored to it. For example, continuous flows usually involve liquid substances and batch wastewater treatment involves working with compound powder substances. Separating the sludge from the clean water can be done using the continuous or batch method.

It is also the type of wastewater type used in closed recylcing systems. For example, wastewater recycling is encountered in plastic recycling. In plastic recycling, the water used to wash plastic is reused. This wastewater is then contained in a closed system and is treated by bypass at wastewater treatment plants.

For companies that generate wastewater, it is important that if they discharge the water, the set standards are met in wastewater treatment or wastewater purification. It is also important to consider the operating costs involved. These must be in proportion to the result achieved. This includes an effective product with the right dosage, which is appropriate for the type of wastewater.

Frequently Asked Questions

What is wastewater treatment?

In biological wastewater treatment, wastes are filtered out of water using bacteria. Physical-chemical treatment involves adding chemicals. Wastes can be organic (like food scraps) or chemical (manufactured substances) which nature struggles to decompose, potentially causing environmental issues.

How does wastewater treatment work?

Wastewater can be processed continuously or in batches. Continuous methods focus on liquid waste, while batch methods work with solid or compound wastes. Effective sludge removal is essential. Companies must meet treatment standards for discharge, balancing operational costs with effective results.

What standards must be met for wastewater discharge?

Companies must adhere to specific regulations governing the discharge of treated wastewater. These standards ensure that the water released into the environment is safe and does not harm ecosystems, requiring effective treatment and management of various types of waste materials.

What types of waste are involved in wastewater treatment?

Wastewater treatment primarily deals with organic waste, such as food and garden debris, and chemical waste from non-natural sources. Proper treatment is crucial, as failing to manage chemical wastes can lead to long-term ecological problems, since nature cannot break them down quickly.

Why is wastewater recycling important?

Wastewater recycling is vital for sustainability, particularly in industries like plastic recycling. By treating and reusing wastewater, businesses can minimize water consumption and environmental impact. Closed-loop systems ensure the recycled water is effectively managed, adhering to necessary treatment standards.

Bio-Based Industry Contacts

Tom Pruymboom

Sales Director

Area Worldwide

Jan Siert Tjeerdsma

Project manager

Technical Specialist

Bio-based & Environmental – Related Articles

Artificial Intelligence and Machine Learning are Moving Up into Mixing Technology

In the ever-evolving landscape of industrial technology, artificial intelligence (AI) and machine learning (ML) are making significant strides in various sectors, including mixing technology. Jongia Mixing Technology is at the forefront of this revolution, integrating state-of-the-art sensor technology with advanced

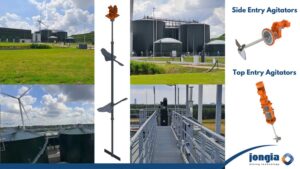

Jongia Mixing Technology‘s Biogas Production program

Optimizing Biogas Production with Jongia’s Innovative Technology Jongia is leading the way in improving biogas production with its advanced mixing solutions. In the biogas industry, effective mixing is key to maximizing energy output, minimizing power consumption and optimizing system efficiency.

VVTI Biogas Tilburg

VTTI Biogas Tilburg is developing a new bio-energy facility, focusing on processing organic waste. The plant is expected to produce approximately 23 million cubic metres of biogas annually. A portion of this will be converted into green gas for the