Concave turbines are often called “the next generation” turbines as they significantly perform better compared to conventional “Rushton” turbines. However, in most all engineering books and studies, the one and only turbine in which is referred to, is the Rushton turbine. Both types are applied for the same duties: Gas dispersion, Fermentation and Bioreactors.

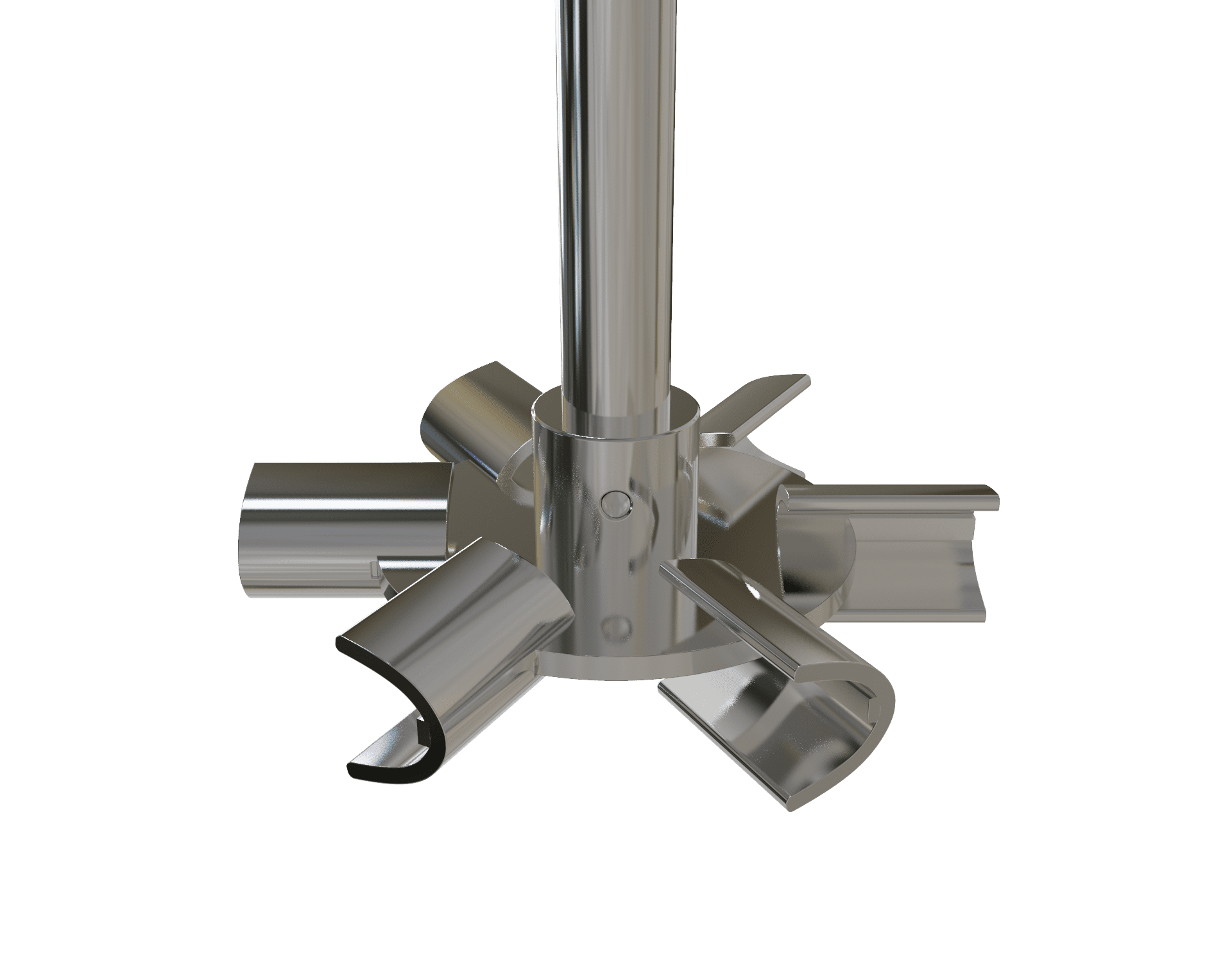

It’s secret is in the “Channels”

Although the genuine design of the Concave turbine looks familiar to the Rushton turbine, specifically the “channels” are the big difference which enable the concave turbine to perform much better. The “channels” take care of a higher output and Jetstream without the cavitation effect. Due to the stronger forces in flow coming from the channels, the concave turbine is much more stable in its variations of speed. Jongia’s Concave turbine has 6 channels in place. This is comparable with the amount of blades on the Rushton turbine.

Gas Dispersion performance without increased power input

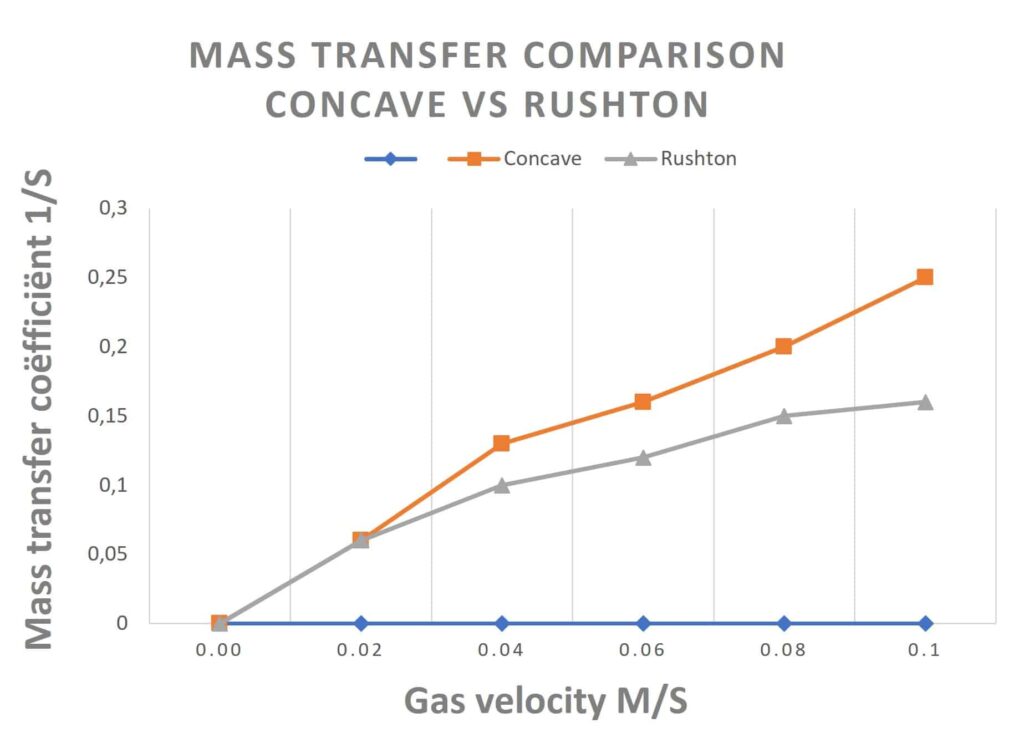

Due to its shape, such turbines demand for a certain consumed power. This consumed power easily increases when rotations are increased. When compared to the Rushton Turbine, by increasing the rotational speed, the Concave Turbine consumed power rate is significantly less affected. Which claims for the Concave Turbine to beat the Rushton Turbine.

If gas dispersion is concerned, high amounts of gas and power are demanded to optimize the process in which the Turbine is running. So, all reduction of power is welcome, certainly when the Turbine is performing equally or even better in comparison to the conventional process parameters.

This benefit calls for the Concave Turbine to beat it’s opponent. The concave turbine can handle approximately four times more gas in comparison to the Rushton turbine! When the gas is added, the power consumption of the Rushton Turbine is decreased significantly, while the Concave Turbine is nearly decreased. This makes the Concave Turbine efficient and stable in his performance. This constant performance also means that the mass transfer output is also more constant in comparison to the Rushton turbine.

All in all, we can conclude

Concave Turbine is in benefit vs Rushton Turbine for:

- Approximately four times higher gas volume handling for better dispersion

- Flat rate of power consumption

- Very stable performance, in changing conditions

- Can easily handle increased viscosities

- Constant output

Concave Turbine

Concave Turbine Mixing Element The shape of the Concave turbine enabled fluids and gasses to be mixed together, dispersed without the mixing element becoming unstable. This is due to the fact that is has a radial flow and is self-balancing.

Vessel lay-out and configuration

Location of the Concave Turbine in comparison to the Rushton Turbine can be equal. However, the Concave Turbine can be placed more closer to the sparger, which allows you to improve your set-up configuration or enable you to operate with the system at a lower volume of the reactor!

In some cases it is quite usual to include an Axial turbine or Hydrofoil turbine to improve the flow in the vessel, these are not needed if the volume in the reactor / tank is low and only one or two Concave Turbines are applied.

The image below shows the performance differences between the Rushton Turbine and Jongia’s Concave Turbine.

Want to know more about Jongia ‘s Concave Turbine mixing element or other mixing elements from Jongia Mixing Technology?

Feel free to visit the website to read more about them, then follow this shortcut or feel free to contact us at Info@www.jongia.com

We are happy to talk to you about the most challenging mixing solutions!

Contact our specialized team for all your questions

Bart Brouwer

Area Sales Manager

Area Worldwide

Sijko van der Veen

Application Engineer

Technical Specialist

Related Articles

The Double Acting Axial Flow Turbine type AST-MTE mixing element

Operation of an AST-MTE Element Operation of an AST-MTE Element This element can be used in both CW (clockwise) and CCW (counterclockwise) directions. In one case, the inner AST element is downward-pumping with the outer tips pumping upward, and in the other case, it’s the opposite.This element is highly effective

High-Speed Disperser Technology: The Engineering Behind Effective Mixing

A Technical Guide by Jongia Mixing Technology Core Function High-speed dispersers excel at three critical tasks: Fracturing powder agglomerates into fine particles Creating uniform powder distribution throughout liquid mediums Facilitating complete dissolution of soluble materials Operating Principles High-speed dispersers transform rotational energy into mixing power through a specialized mechanism: The

VVTI Biogas Tilburg

VTTI Biogas Tilburg is developing a new bio-energy facility, focusing on processing organic waste. The plant is expected to produce approximately 23 million cubic metres of biogas annually. A portion of this will be converted into green gas for the Dutch gas grid, which is sufficient to cover the annual