Last week, Biorefinery Solutions (BRS) visited Jongia in Leeuwarden for a full day of training “Mixing & Stirring”.

The training was based on the process which Biorefinery Solutions applies on daily basis and was therefor matching their demand on process knowledge about Mixing and Stirring.

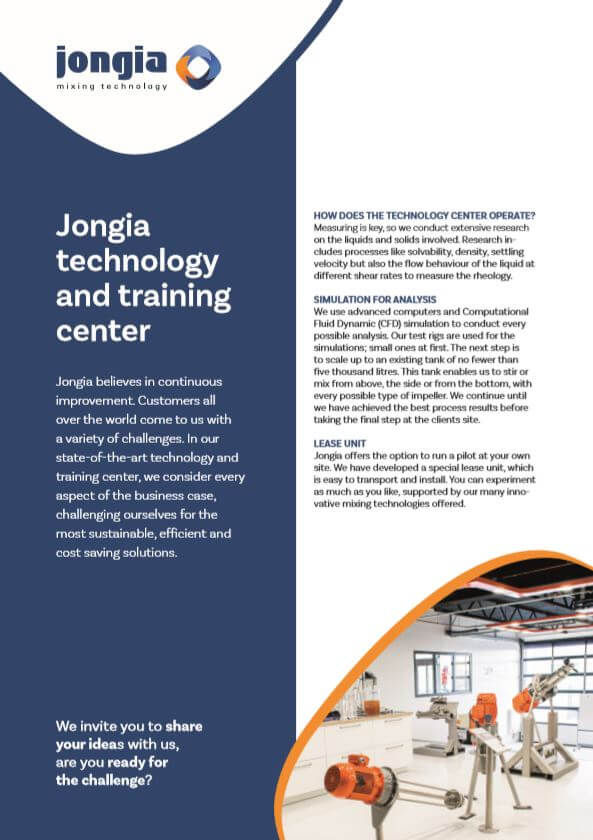

It turned out to be a very successful day, due to the combined knowledge and useful workshop in Jongia’s Technology Centre.

If you would like to know more about tailor-made training material on Process technology, Mixing & Stirring, Please contact Jongia Mixing Technology at your earliest convenience at: info@jongia.com

TECHNOLOGY CENTER

For more information about Jongia’s Technology Center, please visit our Technology Center Page

Contact our specialized team for all your questions

Teun van der Spek

Area Sales Manager

Related Articles

Jongia Mixing Technology Agitators in Process Installations

This reactor setup from Veenbrink RVS, equipped with Jongia agitators, forms the foundation for polymer production. The system is applied in an ATEX classified zone: the equipment zone 1 IIB T2, whilst the space itself is designated as zone 2

Steinfort Glass selects Jongia Mixing Technology

Meet Mr. Gerlof Reineker, general manager of Steinfort Glas in Franeker. Steinfort Glass specializes in processing flat glass for various applications. The company purchases large sheets of glass and processes them into products such as shower doors, office glazing, bus

Jongia agitators with Nord Maxxdrive gearboxes for Smits Group biogas plant

Jongia Mixing Technology recently delivered a series of agitators with Nord Maxxdrive gearboxes for the biogas plant of Brabant-based agricultural company Princepeel, part of the Smits Group. These ‘heavy duty’ Agitators optimally withstand the high torques required to move the