Since Jongia introduced its revamped heavy duty side entry mixer type RWM also known as the Sydmikser, it has been growing in popularity. Clients, in particular in the petrochemical industry, were quick to embrace the compactly built robust mixer. Jongia’s dedicated International Sales Manager William Noordink puts it this way: “We’ve seen a significant growth in the sales of the RWM. I just recently returned from Spain where we’ve visited a number of clients who were equally enthusiastic about the potential of this powerful machine.”

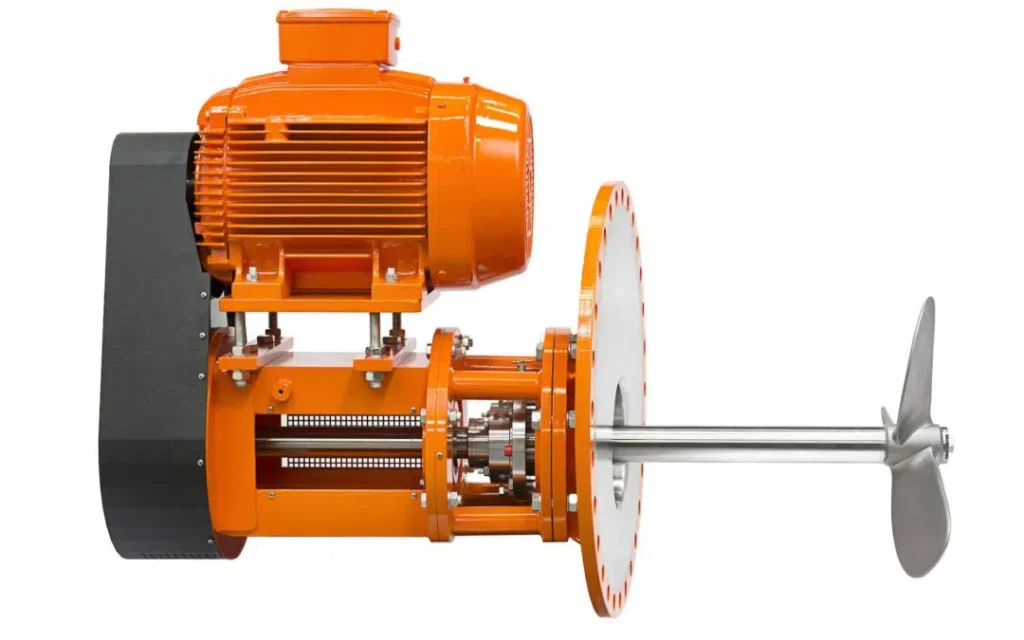

Jongia’s side entry mixer, type RWM, unique because of its robust design, but even more so thanks to its open construction and innovative shut-off device.

When revamping the mixer which is also known as Sydmikser Jongia opted for a unique shut-off device allowing a storage tank to be shut off from the ambient environment. It’s based on an external shut off device, when activated, there is no radial/axial displacement of the shaft. Jongia has designed the conical seat in such a way that the conical ring (mounted on the shaft) is pulled into the conical seat. That way the shaft (including bearings and seal) remains in its position, whilst the conical ring is being closed. Once the shut off device is engaged, the seal can easily be exchanged from the immobilized shaft. Due to the open construction of the mixer the shut off device is easy accessible with just a wrench.

The unique design has already gained recognition from customers such as Total refinery, Koole Tankstorage Minerals, VOPAK and Odfjell terminals. These end users have opted for the open construction side entry mixers in combination with a double mechanical seal system. In doing so maximum safety and emission control on site are ensured.

The Sydmiksers have a design lifecycle of 20 years and require only the minimum in OPEX cost. Although the mixer has a standardized modular design, every single mixer will be engineered and dedicated to the process application. Every mixer manufactured in our workshop must meet the requirements of an especially developed test protocol. These tests include among others a Dry Run Test, Vibration test and Noise Measurement test. All mixers will be assembled completely at the Jongia workshop for the testing cycle and are prepared for transport afterwards.

Learn more about the RWM and its unique features here. Or contact our International Sales Manager, Bart Brouwers.

Contact our specialized team for all your questions

Bart Brouwer

Area Sales Manager

Area Worldwide

Technical Questions?

Jan Siert Tjeerdsma

Project Manager

Technical Specialist

Related Articles

The Double Acting Axial Flow Turbine type AST-MTE mixing element

Operation of an AST-MTE Element Operation of an AST-MTE Element This element can be used in both CW (clockwise) and CCW (counterclockwise) directions. In one case, the inner AST element is downward-pumping with the outer tips pumping upward, and in

Do I need a Bottom Bearing for my agitator?

Do I need a Bottom Bearing? The installation of a bottom bearing is not mandatory. While it offers certain advantages, there are also drawbacks to consider. It is important to note that the bottom bearing functions more as a displacement

High-Speed Disperser Technology: The Engineering Behind Effective Mixing

A Technical Guide by Jongia Mixing Technology Core Function High-speed dispersers excel at three critical tasks: Fracturing powder agglomerates into fine particles Creating uniform powder distribution throughout liquid mediums Facilitating complete dissolution of soluble materials Operating Principles High-speed dispersers transform