Battery chemicals can be grouped under three main categories,

- electrolytes for secondary lithium-ion batteries,

- electrolytes for primary lithium batteries,

- electrolytes for super-capacitors.

As one of the four vital constituents of lithium batteries (i.e., anode, cathode, separator, electrolyte), electrolytes for lithium-ion batteries are composed of solvent, lithium salt solute and additives.

Responsible for transporting lithium ions, it is regarded as the “blood” of the battery, acting as a critical factor to ensure high voltage, high specific energy and other advantages of lithium-ion batteries.

Electrolyte for one million electric cars

A large Chinese battery manufacturer has been manufacturing electrolyte, the main component of lithium-ion batteries, for over a quarter of a century. Today it is the most popular way to power electric cars and electronic devices such as smartphones, laptops, Bluetooth headphones, and pacemakers. Such batteries perform better while being more environmentally and user-friendly: they have a longer life and feature high energy density..

In Srem, Poland, this large Chinese battery manufacturer has build a new facility in 2021. This new factory is designed to yield a production capacity of 40,000 tons of electrolyte per year. This large “European” proportion contributes to the other five factories in China which supply a total of 170,000 tons electrolyte per year.

The main purpose of the electrolyte production facility in Poland is for the automotive market and electric cars in particular. With this new factory, Poland and Srem in particular plays a large role in the European Lithium battery production for electric cars.

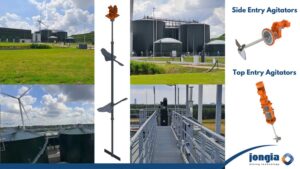

Jongia has been awarded to supply the agitators for the electrolyte production process. With a number of agitators tailor made for each of the process tanks, and equipped to serve the electrolyte production, Jongia has proven to be the right choice for agitators in the electrolyte battery production market!

Interested in Jongia’s portfolio and experience for Electrolyte battery production? Please feel free to contact the Jongia team at your earliest convenience.

Contact our specialized team for all your questions

Tom Pruymboom

Sales Director

Area Worldwide

Bart Brouwer

Area Sales Manager

Area Worldwide

Technical Questions?

Jan Siert Tjeerdsma

Project Manager

Technical Specialist

Related Articles

Artificial Intelligence and Machine Learning are Moving Up into Mixing Technology

In the ever-evolving landscape of industrial technology, artificial intelligence (AI) and machine learning (ML) are making significant strides in various sectors, including mixing technology. Jongia Mixing Technology is at the forefront of this revolution, integrating state-of-the-art sensor technology with advanced

Jongia Mixing Technology‘s Biogas Production program

Optimizing Biogas Production with Jongia’s Innovative Technology Jongia is leading the way in improving biogas production with its advanced mixing solutions. In the biogas industry, effective mixing is key to maximizing energy output, minimizing power consumption and optimizing system efficiency.

Difference between precipitation and crystallization

Precipitation and crystallization are both processes involved in the formation of solid substances from a solution, but they occur under different conditions and result in different outcomes. 1. Precipitation: Precipitation occurs when a solid substance forms from a solution as