What are Bioreactors and Fermenters?

Bioreactors and Fermenters are culture systems to produce cells or organisms. They are used in various applications, including basic research and development, and the manufacturing of biopharmaceuticals, food and food additives, chemicals, and other products.

A broad range of cell types and organisms can be cultivated in bioreactors and Fermenters, including cells (like mammalian cell lines, insect cells, and stem cells), microorganisms (like bacteria, yeasts, and fungi), as well as plant cells and algae. The words “Bioreactor” and “Fermenter” are basically the same thing.

Chemicals and materials from renewable raw materials, such as biomass, will become increasingly important in the circular economy of the future. Fermentation conversion technology therefor, is going to be the most important part in this process.

Fermentation involves the digestion of sugars in biomass by selected micro-organisms, producing certain chemicals and occasionally CO2. As example, think about the production of wine. Ethanol (alcohol) production is a very well developed application of fermentation technology. For instance, bioethanol is already being produced on a large scale from biomass. Not for human consumption, but for sustainable biofuels. Fermentation has also long been used commercially in the food industry and lactic acid production.

Aeration / Gasification

The purpose of aeration in fermentation is to supply oxygen and to remove carbon dioxide from microbial cells suspended in the fluid. The amount of aeration is of high importance, since it controls the rates of cell growth and product formation.

Mixing in the gas and liquid phases affects the aeration characteristics of the fermenter.

The following types of aeration are applied:

- Sparged fermenters with an agitator,

- Bubble column fermenter,

- Loop fermenters.

In the Sparged fermenter with an agitator, gas, usually air, is sparged into the fluid, which is then stirred by the agitator. This is the most common type of fermenter. In this process the agitator is of high influence of the fermentation process, such fermenters are used most widely for various aerobic fermentations.

The bubble column is a cylindrical vessel containing a liquid through which gas is bubbled; this can be operated continuously with either counter- or co-current flows of liquid or gas.

In the Loop fermenter, liquid is recirculated by the difference of the average densities of the broth between the gassed and ungassed sections or by means of a pump or fluid jet.

Bioreactors

A bioreactor refers to any manufactured device or system that supports a biologically active environment. The bioreactor can be a vessel in which a biochemical process is carried out which involves organisms or biochemically active substances derived from such organisms.

This process can either be:

- Aerobic or

- Anaerobic

Bioreactor vessels are commonly cylindrical, ranging in size from litres to cubic metres, and are often made of stainless steel. It may also refer to a device or system designed to grow cells or tissues in the context of cell culture. These devices are being developed for use in tissue engineering or biochemical/bioprocess engineering.

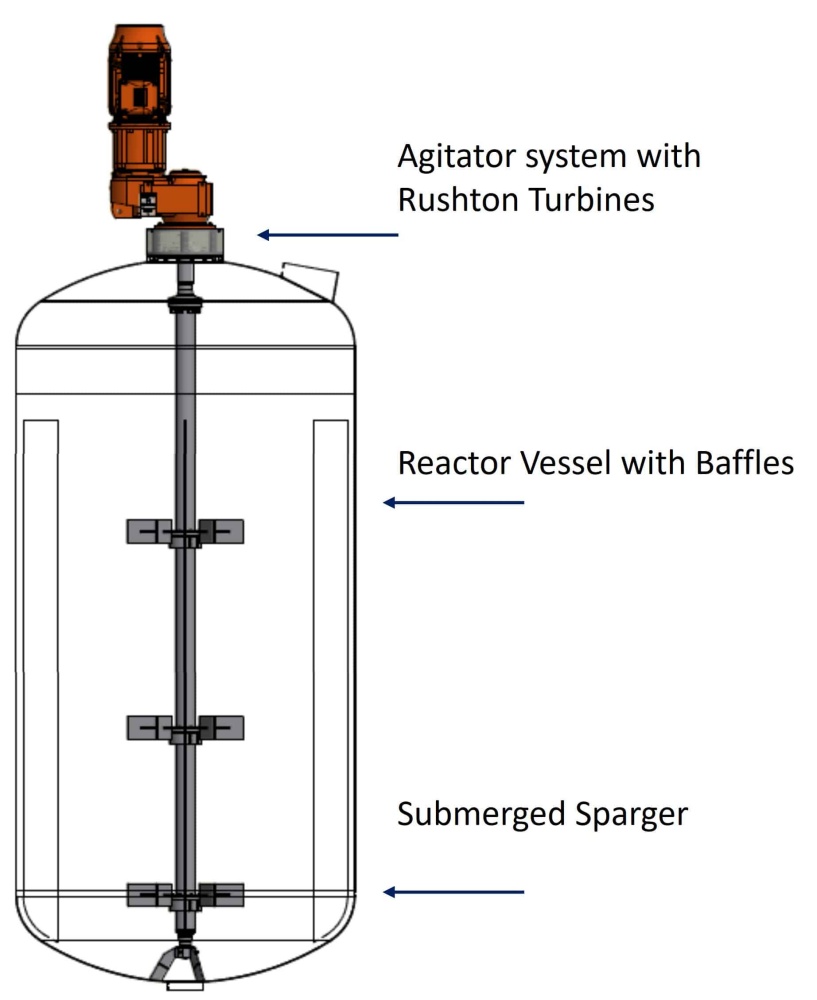

General structure of a continuously agitated type of Bioreactor

On the basis of mode of operation, a bioreactor may be classified as batch, fed batch or continuous (e.g. a continuous stirred-tank reactor model).

Organisms or biochemically active substances growing in bioreactors may be submerged in liquid medium or may be anchored to the surface of a solid medium. Submerged cultures may be suspended or immobilized. Suspension bioreactors may support a wider variety of organisms, since special attachment surfaces are not needed, and can operate at a much larger scale than immobilized cultures. However, in a continuously operated process the organisms will be removed from the reactor with the effluent. Immobilization is a general term describing a wide variety of methods for cell or particle attachment or entrapment. It can be applied to basically all types of biocatalysis including enzymes, cellular organelles, animal and plant cells and organs. Immobilization is useful for continuously operated processes, since the organisms will not be removed with the reactor effluent, but is limited in scale because the microbes are only present on the surfaces of the vessel.

Bioreactors with agitators make use of the process technique of cultivation in the bioreactor itself by mixing or stirring .

A stirred-tank bioreactor system consists of several parts such as:

- Reactor vessel which is filled with medium in which cells are cultivated.

- Components, within or attached to the vessel or the vessel head, to measure and adjust the culturing conditions, such as feed lines and sensors.

- A control system comprising external components used to adjust the culturing conditions (for example pumps) and control software creating optimal cultivation conditions like incubators and shakers, bioreactors allow for the creation of optimal environmental conditions for the growth of cells or microbes. They differ, however, in how these are established.

- Cooling Jacket with temperature sensors

And last, but certainly not least:

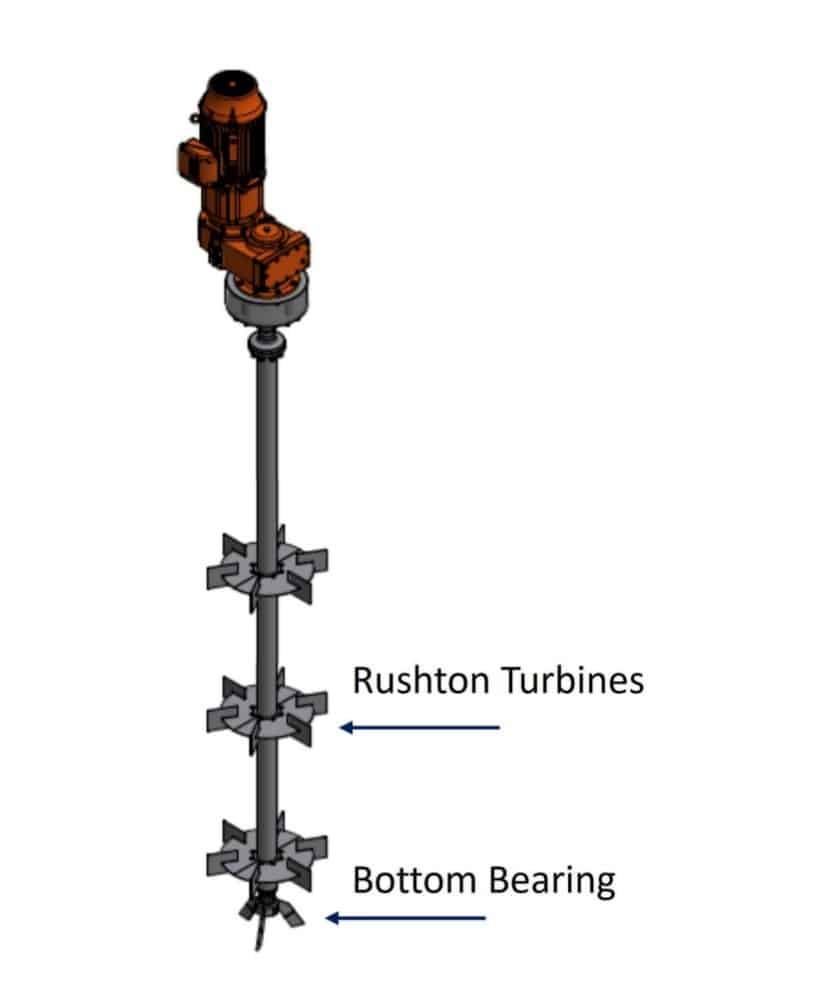

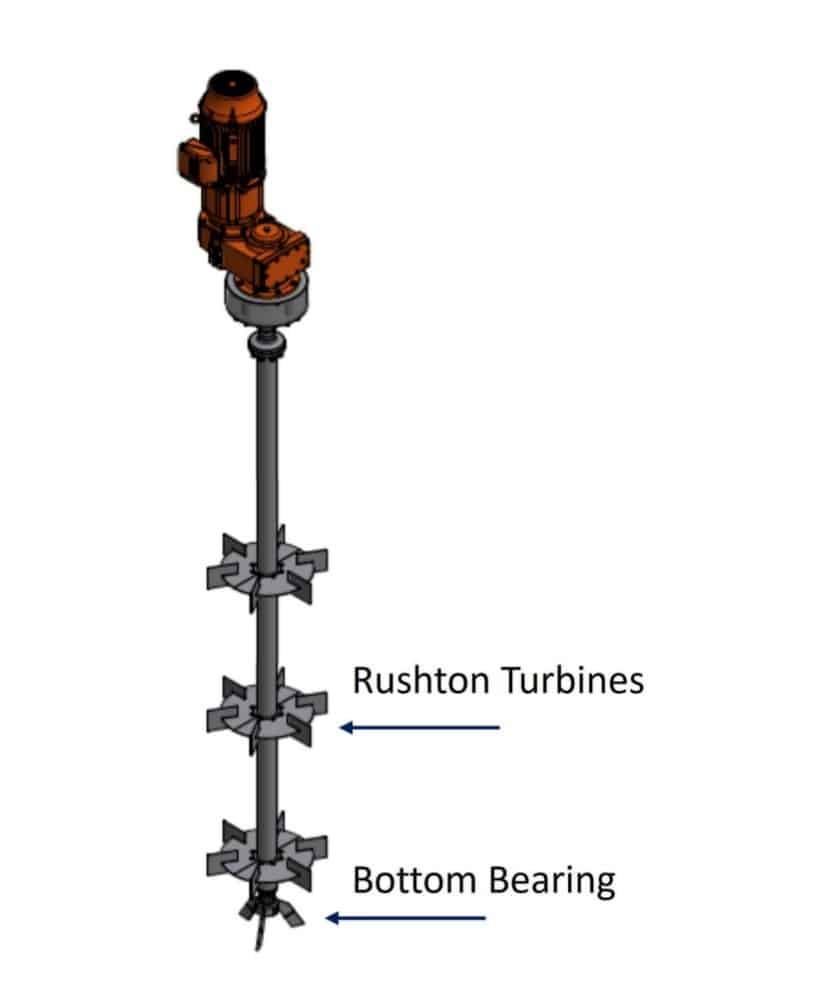

- Agitator or Mixer; in the bioreactor in which the culture is stirred with a series of Mixing Elements. Most commonly applied Mixing Elements in Fermentation processes are Rushton Turbines or Concave Turbines.

These Mixing Elements have 2 different mixing duties:

- Improve the aeration process

- Create an upwards flow to ensure that all parts of the vessel are mixed continuously.

In a bioreactor, not only are bacterial, yeast, and suspension cell cultures constantly mixed, but also cultures of adherent cells attached to a growth matrix.

The temperature of the culture medium is continuously monitored with a temperature sensor. To regulate it, the vessel is equipped with a jacket suitable for heating or cooling.

Establishing aerobic conditions, oxygen is transferred from the surrounding air to the culture medium.

This process is more efficient when Mixers or Agitators are applied since these will increase exposure of the liquid surface.

Baffles placed inside the reactor vessel

A reactor vessel equipped with baffles can increase the agitation of a fermentation broth and increase the reaction time of the substrate in the reactor, improving the hydrogen production performance and energy conversion rate. It is therefor most common to apply baffles inside reactor vessels with agitators.

Want to know more about Jongia ‘s fermentation process or Bioreactors, Rushton Turbine, the Concave Turbine or other Mixing Elements from Jongia Mixing Technology?

Feel free to visit the website to read more at our technology center page or Rushton mixing element product page.

Do you want to speak to a Mixing Specialist? Please contact feel free to contact us at Info@www.jongia.com

We are happy to talk to you about the most challenging mixing solutions!

Contact our specialized team for all your questions

Tom Pruymboom

Sales Director

Area Worldwide

Bart Brouwer

Area Sales Manager

Area Worldwide

Related Articles

The Double Acting Axial Flow Turbine type AST-MTE mixing element

Operation of an AST-MTE Element Operation of an AST-MTE Element This element can be used in both CW (clockwise) and CCW (counterclockwise) directions. In one case, the inner AST element is downward-pumping with the outer tips pumping upward, and in

High-Speed Disperser Technology: The Engineering Behind Effective Mixing

A Technical Guide by Jongia Mixing Technology Core Function High-speed dispersers excel at three critical tasks: Fracturing powder agglomerates into fine particles Creating uniform powder distribution throughout liquid mediums Facilitating complete dissolution of soluble materials Operating Principles High-speed dispersers transform

VVTI Biogas Tilburg

VTTI Biogas Tilburg is developing a new bio-energy facility, focusing on processing organic waste. The plant is expected to produce approximately 23 million cubic metres of biogas annually. A portion of this will be converted into green gas for the