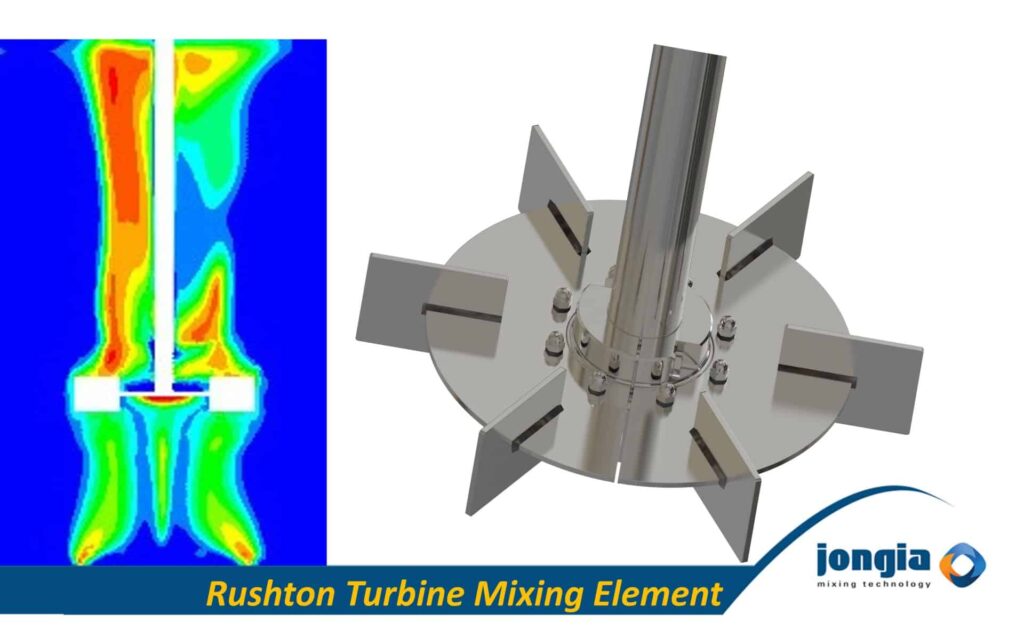

The Rushton disc turbine or Rushton turbine is a radial flow impeller used for many mixing applications and particularly for Gas Dispersion and Fermentation applications in process engineering and was invented by John Henry Rushton.[1]

The design of the Rushton turbine is based on a flat horizontal disk, with flat, vertically-mounted blades. In most cases, the disc has 6 vertically mounted blades, which are mounted at 1/3rd of the disc and create a radial flow.

What is the shape of the Rushton Turbine?

The shape of the Rushton turbine enabled fluids and gasses to be mixed together, dispersed without the mixing element becoming unstable. This is due to the fact that is has a radial flow and is self-balancing.

The flow is discharged radially outward to the vessel wall with half the flow directed upward, and half the flow directed downward.

Rushton turbine is used in process applications in which high shear or turbulence is necessary. The impeller design is best suited for gas liquid contacting. Certainly when the Gas is introduced under the impeller via a sparger.

The turbine guides the gas along a path of optimal liquid contact and prevents the gas from following a direct vertical path alongside the shaft of the agitator, which would otherwise result in minimum contact. The disc also prevents gas bubbles from passing through the low shear zone around the impeller hub.

Rushton turbines have a high shear effect. Vertical transportation of the fluid in the tank body should be supported by means of axial flow turbines or propellers. Therefor in many cases a combination of these mixing elements on an agitator shaft is what is configurated.

Jongia Mixing Technology has discovered that with Gas dispersion through a Sparger ring, the feeding turbines (i.e. the Axial Flow Turbine or the Propeller) will need to pump upwards, bottom-over-top in order to support the gas from flowing upwards in the process. This to make sure that the Fermentation process will run optimally.

What are the Advantages of the Rushton turbine?

Although they can be used for any type of single- and multiple-phase mixing duty, they are most effective for gas–liquid and liquid–liquid dispersion and provide higher shear and turbulence levels with lower pumping.

With suitable baffles these flows are converted to strong top-to-bottom flows both above and below the impeller.

In which applications do we see Rushton turbines?

- Fermentation,

- Gas Dispersion,

- Waste and fiber processing in pulp and paper industries,

- low level mixing.

The Rushton turbines usually runs on a high rotation number. Because of the high RPM, the Rushton Turbine often consumes a rather large amount of power.

A variant of the Rushton turbine is the impeller in which the impeller blades are concave, instead of flat. Such a Turbine variant is called a Concave Turbine.

This feature or design execution has the advantage that it is not entrapping Gas in any way. The advantage is that the Gas will have a more efficient property in the process.

Want to know more about Jongia ‘s Rushton Turbine mixing element or other mixing elements from Jongia Mixing Technology?

Feel free to visit the website to read more about them, then visit the Rushton mixing element product page or feel free to contact us at Info@www.jongia.com

We are happy to talk to you about the most challenging mixing solutions!

Contact our specialized team for all your questions

Tom Pruymboom

Sales Director

Area Worldwide

Bart Brouwer

Area Sales Manager

Area Worldwide

Related Articles

VVTI Biogas Tilburg

VTTI Biogas Tilburg is developing a new bio-energy facility, focusing on processing organic waste. The plant is expected to produce approximately 23 million cubic metres of biogas annually. A portion of this will be converted into green gas for the

Homogenization and Cooling in Diary Cream Production

Utilizing Jongia’s Cup Mixer Homogenization is a standard procedure employed in dairy cream production to ensure the consistent distribution of fat globules in both milk and cream. This process, achieved through a high-pressure homogenization apparatus, breaks down and disperses fat

Tutorial: Rushton Turbine vs Concave Turbine

We are happy to announce on behalf of Jongia Mixing Technology that we have just launched a new tutorial on our website! This time, we take you into the world of mixing technology with an in-depth comparison between the “Rusthon