Utilizing Jongia’s Cup Mixer

Homogenization is a standard procedure employed in dairy cream production to ensure the consistent distribution of fat globules in both milk and cream. This process, achieved through a high-pressure homogenization apparatus, breaks down and disperses fat globules to create a stable emulsion. By reducing fat particles into smaller sizes, homogenization enhances the product’s texture, taste, and shelf life, meeting quality standards and providing a consistent experience for consumers.

Optimizing Dairy Cream Cooling and Transport to Preserve Quality and Prevent Viscosity Issues

During the process of dairy cream production, the cream advances to the cooling sections within the heat exchanger, where a meticulous cooling process unfolds. This precision aims to concurrently reduce the temperature to an optimal 8 °C in the deep cooling section before the cream progresses to the ripening tanks. Maintaining an average temperature of 8 °C proves to be ideal for cream with a fat content ranging from 35 to 40%. However, higher fat content creams necessitate elevated cooling temperatures to prevent viscosity-induced clogging.

Excessive fat viscosity poses risks, including a sharp pressure rise, potential damage to fat globules, and even butteroil leakage. To maintain product quality, the process may be paused, involving system flushing, cleaning, and restart procedures. Efforts are made to minimize shearing and turbulence during cream transportation from the cooling section to the processing tank. This meticulous approach, facilitated without a pump and with adequately dimensioned piping, ensures a smooth transfer, with pressure provided by the booster pump. The careful coordination of this cooling and transportation process proves vital for preserving the cream’s quality, preventing undesirable damage, and ensuring optimal fat crystallization in the final product.

Tutorial: How does the cupmixer work?

Jongia’s Cup Mixer: Revolutionizing Cream Production with Enhanced Mixing Efficiency and Stability

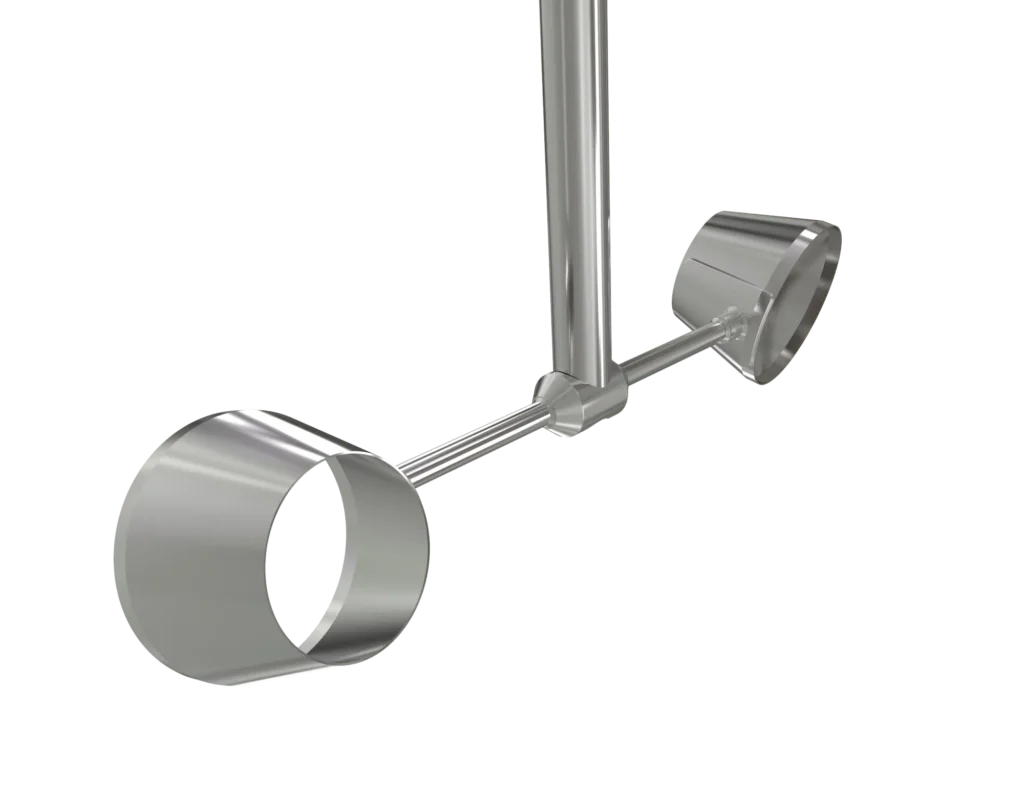

The introduction of the cup mixer, a specialized stirring element by Jongia Mixing Technology, further refines and elevates the cream production process. This unique mixer is particularly gentle on viscous products, it maintains fluid homogeneity at the right temperature. Horizontally placed in the tank, the cup mixer can consist of one or more cup sets stacked above each other on the stirring shaft, enhancing mixing efficiency.

Integrated into homogenization and cooling, the cup mixer complements the high-pressure homogenizer, refining particle size distribution and improving emulsion stability. As the homogenized liquid progresses to the cooling sections, the cup mixer minimizes shearing and turbulence, preventing viscosity-induced clogging and reducing the risk of pressure anomalies. In instances where a second homogenization step is deemed necessary, the cup mixer’s contribution remains significant, further refining particle size distribution and enhancing emulsion stability. Also, the Cup mixer’s shape and performance avoids foam to build and is able to run on a fluid level, which enables you to empty the tank while the Cup mixer unit is keeping the tank content homogeneous.

Importance of Cup Mixer in Dairy Cream Production Quality

The decision to include the cup mixer in homogenization and cooling stages is rooted in its role in elevating overall cream quality. Ensuring efficient mixing, refining particle distribution, and enhancing emulsion stability, the cup mixer stands as a crucial component in the production of consistently appealing and high-quality dairy cream.

While specific details about the cup mixer’s functionality may vary, its importance in achieving optimal cream characteristics is undeniable in the complex process of dairy cream production.

Want to know more?

As with all production processes, mixing the various products requires a specific approach and an appropriate agitator. Jongia Mixing Technology has the knowledge and experience to give you comprehensive advice in this field. Do you have any questions about the BioFoil® propeller or any other agitator? Please do not hesitate to contact us.

Contact our specialized team for all your questions

Tom Pruymboom

Sales Director

Area Worldwide

Bart Brouwer

Area Sales Manager

Area Worldwide

Technical Questions?

Sijko van der Veen

Application Engineer

Technical Specialist

Tutorial: Batch Crystallization

Jongia Mixing Technology has initiated countless mixing processes all over the world with the help of her agitators. In a number of these mixing processes, crystallization is of great importance to obtain the desired final product. In this tutorial, Area

The cupmixer: from request to solution

The cupmixer is a stirring element that can be widely deployed. It can therefore be used in a variety of industries. Nevertheless, a cupmixer is primarily used for mixing products for which it is important that no air is entrapped and that homogenous quality

Tutorial: How does the cupmixer work?

The cupmixer is a special stirring element. It is used in the mixing process of viscous products. The cupmixer is also suited for sensitive viscous products that are easily damaged. A cupmixer is placed in the tank horizontally and can