Using the UZ-Mixing Element is not the solution for every application. Nevertheless, in the food, dairy, pharmaceutical and chemical industries, the UZ-Mixing element is frequently applied. For example, in the dairy industry to produce Yogurt since it does not damage the Yogurt product during production. Jongia Mixing Technology, from application to solution about Yoghurt production is highlighted in this article.

Every Customers request is different

A customer request arrives at Jongia Mixing Technology in different ways. Jongia Mixing Technology then makes a selection of the most suitable mixing & stirring element such as the UZ mixing element based on the customer request. Some of the questions that are asked to the customer: what is the objective, what do they want to achieve in the tank and what are the dimensions of the tank.

If Jongia Mixing Technology has previously realized the same product by means of a UZ-mixing element, then that set-up will be validated to the new tank dimensions.

UZ mixing element selection obviously depends on the stirring process

Following the customer’s answers, Jongia Mixing Technology prepares a quotation containing the process solution. The advantages are mentioned and a detailed description is given why specifically the UZ mixing element is selected.

We have specifically described the advantages of applying a UZ mixing element on this page.

As an example, let’s take the production of Yogurt

The word Yogurt is originally from Turkish and has to do with “kneading.”

Yogurt is a dairy product that consists of milk and lactic acid. This is because the bacteria of the yogurt culture convert the milk sugars from the milk into lactic acid. Lactic acid is created by fermentation. In this fermentation process, milk sugars are converted into lactic acid by lactic acid bacteria. Depending on the milk used, yogurt is full-fat, half-fat or low-fat. Yogurt has a more acidic taste than milk and has a thicker texture.

For a product to be called yogurt, it must contain the Yoghurt culture, which are the yogurt bacteria Lactobacillus bulgaricus and Streptococcus thermophilus.

To produce Yogurt, a production process tank filled with milk is used. This can be raw milk as well as pasteurized milk. The protein content and fat content in this milk does determine the Yogurt product, which is why there are also different Yogurt products.

The milk needs to be brought to the right temperature through the heating and cooling jacket of the process tank and, of course, through the agitator. After the right temperature is reached, the yogurt culture is added. The yogurt culture is usually dosed in liquid form.

The yogurt culture consists of bacteria that must do their work at the right temperature, in the liquid.

To mix the yogurt culture, that is, the bacteria neatly with the milk, the UZ-mixing elements of the agitator should shortly mix the yogurt bacteria at a low rotational speed, in order to obtain a homogeneous composition of the tank contents at the right temperature. This temperature is about 40 degrees Celsius.

At 40 degrees Celsius, the bacteria feel comfortable, allowing them to do their work. The bacteria convert the lactoses into lactic acids through the process of fermentation. This fermentation process takes place in the process tank at the right temperature where stirring hardly plays a role. As long as the tank contents are properly stirred beforehand, the bacteria will then do their own work.

Once the acidity of the lactic acid is reached, it is very important that the agitator performs its function properly. This is; ensuring that the temperature goes down by means of cooling. To cool down properly, it is important that the agitator runs quietly and does not damage the product in the tank. The UZ mixing element is ideally suited for this since:

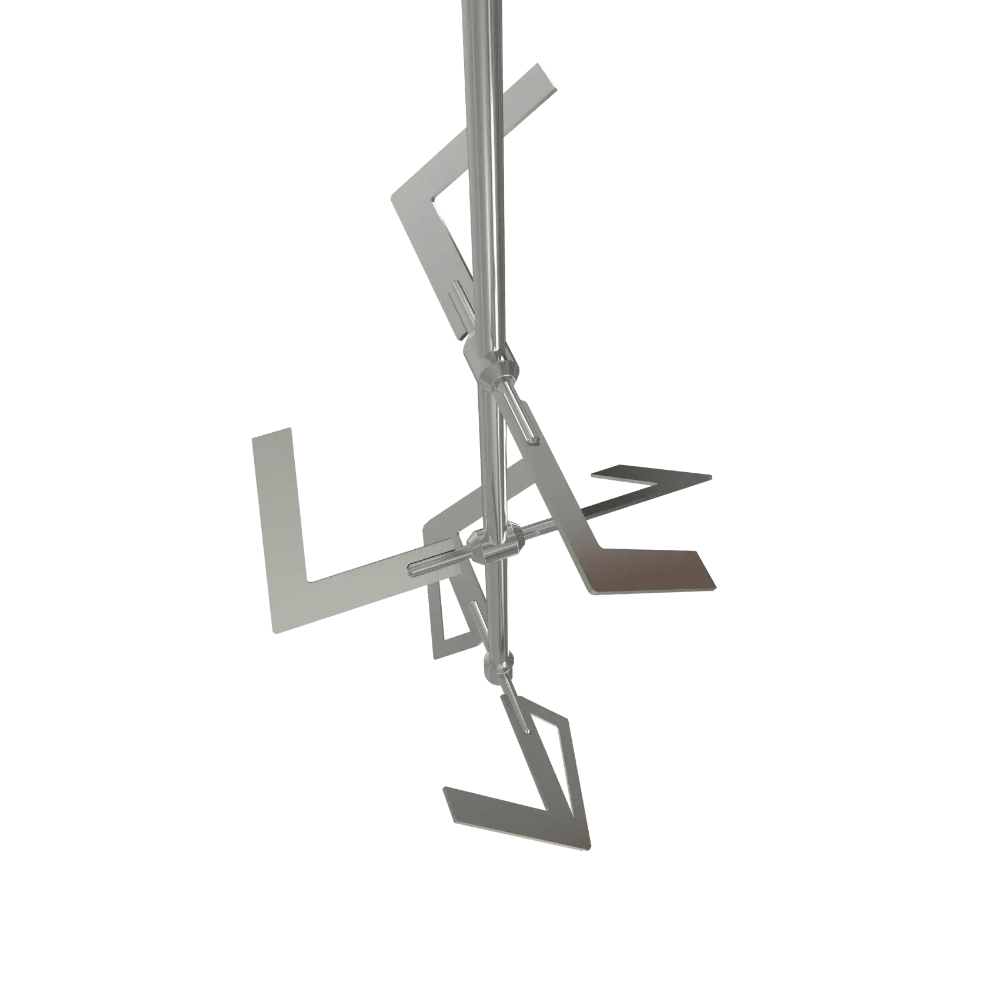

- It can Push, Scoop and Pump.

- It is ideal for medium viscous liquids

- The arms and legs of the UZ-turbines virtually cover the entire tank cylinder in which the agitator operates

- During emptying and filling of the tank, the agitator can just keep rotating on the liquid level

From the 40 degrees operational temperature , the fluid is cooled back to 5-6 degrees by the agitator. This causes the bacteria to become inactive.

The result is Yogurt!

To produce different types of Yogurt, different bacteria can be used in different types of milk. However, the production process remains the same.

This makes Jongia Mixing Technology very capable of achieving the most optimal mixing result with the UZ-mixing element at different dairy producers worldwide.

Would you like to know more about Jongia ‘s UZ mixing element or other mixing elements from Jongia Mixing Technology?

Feel free to visit the website to read more about them, please use this shortcut.

or feel free to contact us at: Info@www.jongia.com

We are happy to talk to you about the most challenging mixing solutions!

Contact our specialized team for all your questions

Bart Brouwer

Area Sales Manager

Area Worldwide

Tom Pruymboom

Sales Director

Area Worldwide

Related Articles

The Double Acting Axial Flow Turbine type AST-MTE mixing element

Operation of an AST-MTE Element Operation of an AST-MTE Element This element can be used in both CW (clockwise) and CCW (counterclockwise) directions. In one case, the inner AST element is downward-pumping with the outer tips pumping upward, and in

High-Speed Disperser Technology: The Engineering Behind Effective Mixing

A Technical Guide by Jongia Mixing Technology Core Function High-speed dispersers excel at three critical tasks: Fracturing powder agglomerates into fine particles Creating uniform powder distribution throughout liquid mediums Facilitating complete dissolution of soluble materials Operating Principles High-speed dispersers transform

VVTI Biogas Tilburg

VTTI Biogas Tilburg is developing a new bio-energy facility, focusing on processing organic waste. The plant is expected to produce approximately 23 million cubic metres of biogas annually. A portion of this will be converted into green gas for the