Insulation

Insulation consists of isolating or sealing something. In the case of thermal insulation, this means so there is a separating layer with low thermal resistance between the cold and heat fronts.

This separating layer keeps the cold out and the heat in, or vice versa if desired (for example, in summer). Thus, a well-insulated home can lead to substantial savings in heating costs.

Proper mixer selection is vital to process optimisation, for that you can rely on our experienced staff of engineers and process technologists.

Types of insulation

There are many different types of insulation, we would like to go over the most commonly used types with you.

- Stone wool

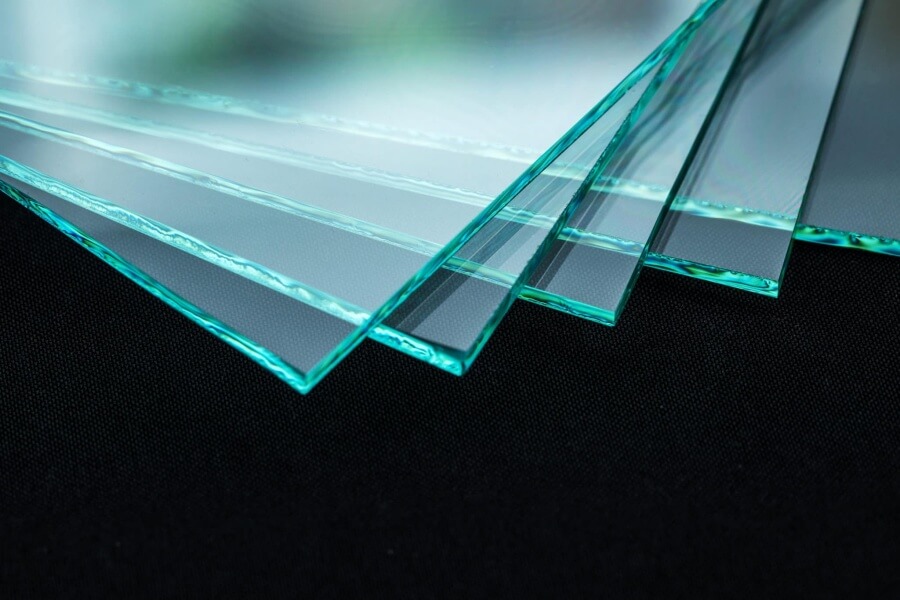

Stone wool is usually made from diabase or basalt, due to these resources it is also called rock wool. Stone wool is a common insulation material and is often used to insulate facades, floors and roofs. In addition to being thermally effective, it is also acoustically insulating. - Glass wool

Glass is made from recycled glass to which sand, soda and limestone are added. This creates a silicate. Like stone wool, it is a very popular insulation material and is often used to insulate walls, floors and roofs. It is thermally good insulation and often fairly inexpensive. - Cellular glass

Cellular glass is also often called foam glass. It is made from recycled glass, sand and feldspar. As these materials are heated, carbon is added, causing the gas mixture to foam up. The material is enormously strong and also very durable. Cellular glass is very suitable as crawl space insulation. It is also used for floors, roofs and facades.

Chemical Applications

Insulation market developments

The global insulation market was valued at $57.95 billion in 2021. Increasing consumer awareness regarding energy conservation is expected to have a positive impact on the market. Due to high gas and energy costs, new forms of insulation are also increasingly being explored. Often, the cost of insulation is relatively lower than the increased energy costs, making people quick to choose to install good insulation.

Frequently Asked Questions

What is insulation?

Insulation involves isolating or sealing spaces to create a barrier with low thermal resistance, either keeping cold air out or retaining heat. This not only enhances comfort but also contributes to significant savings in heating costs, making it essential for energy-efficient homes.

What are the main types of insulation?

The main types of insulation include stone wool, glass wool, and cellular glass. Each type has unique properties like thermal effectiveness and acoustic insulation, and they are commonly used in facades, roofs, and floors, contributing to both energy efficiency and soundproofing.

Why is proper mixer selection important?

Proper mixer selection is crucial for optimizing processes in various applications. Relying on experienced engineers and process technologists ensures that the right mixer is chosen, enhancing efficiency, performance, and overall process optimization in industrial settings.

What are market trends in the insulation industry?

The global insulation market, valued at $57.95 billion in 2021, is experiencing growth due to rising consumer awareness about energy conservation. Increasing energy costs prompt exploration of new insulation forms, often proving to be cost-effective solutions for consumers facing high energy expenses.

How does insulation contribute to cost savings?

Well-installed insulation can lead to substantial cost savings in heating bills by reducing energy loss. This makes investing in insulation financially advantageous, especially in climates where heating costs are significant, and it can quickly offset the installation expense.

Chemical Industry Contacts

Tom Pruymboom

Sales Director

Area Worldwide

Bart Brouwer

Area Sales Manager

Area Worldwide

Jan Siert Tjeerdsma

Project manager

Technical Specialist

Chemical – Related Articles

Difference between precipitation and crystallization

Precipitation and crystallization are both processes involved in the formation of solid substances from a solution, but they occur under different conditions and result in different outcomes. 1. Precipitation: Precipitation occurs when a solid substance forms from a solution as

Tutorial: How does the Counterflow work?

The Counterflow is a very suitable mixing element for mixing processes of medium viscous liquid products such as paints, polymers and biodegradable plastics where starch is the basic component. In this tutorial we show you how the Counterflow moves the

The Counterflow: from request to solution

Mainly in the chemical industry, the Counterflow mixing element is applied in mixing processes of products such as paint, polymers, biodegradable plastics where starch is the basic component and medium viscous liquids. However, what kind of questions do the customers