Sealants

Silicone sealant

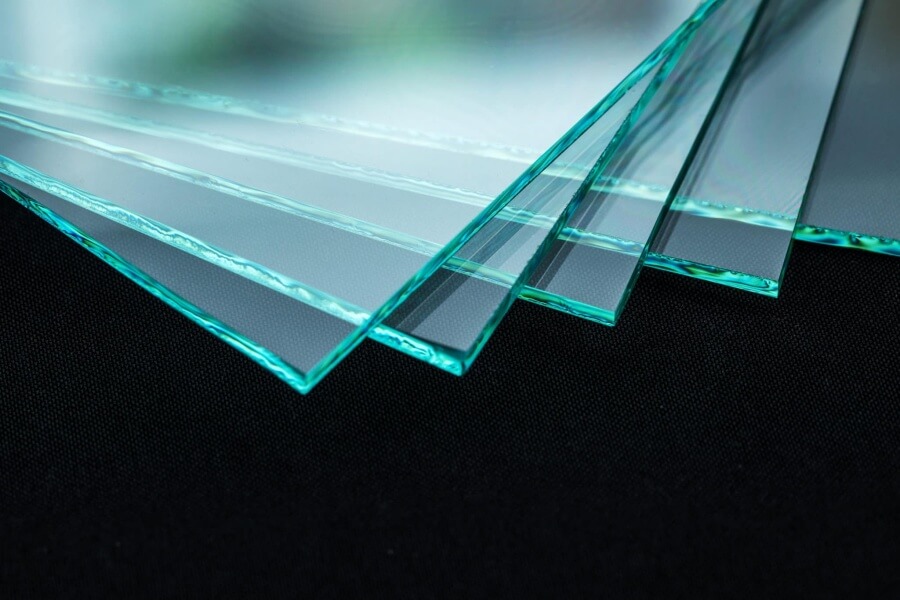

Silicone sealant, also known as glass cement, based on polydimethylsiloxane as the main raw material, is a paste consisted of cross-linking agent, filler, plasticizer, coupling agent, catalyst mixed in a vacuum state. It solidifies at room temperature with water in the air to form elastic silicone rubber. How is the making process of silicone sealant production line?

To make silicone sealant, you should firstly make its basic materials, then make the sealant.

Proper mixer selection is vital to process optimisation, for that you can rely on our experienced staff of engineers and process technologists.

Process steps

The base materials will come to the base material storage tank by the high viscosity pump, slowly adding these materials to the three roller grinding machine, to achieve the fineness requirements.

After grinding of the base materials, put the materials into the mixing unit. And then, adding other ingredients and paste. The mixing unit will be pushed into a multifunctional dispersing machine, starting stirring and high-speed dispersing.

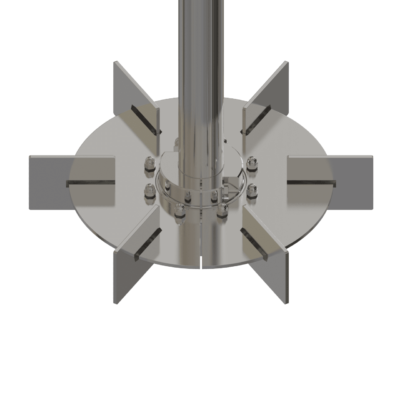

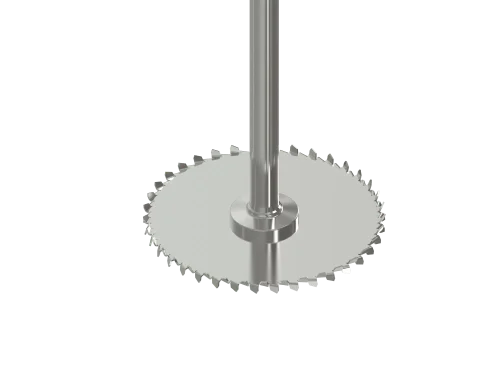

For this, Jongia has its’ High-shear Sawblade or Ruston blade available to do the job. At the same time, starting the vacuum system, drawing out the moisture and air from the materials. Start the cooling system to control the temperature of the materials.

After the production is finished, the mixing tank is pushed into the hydraulic discharging machine, and materials are transported to a material cylinder of the packaging machine; putting the bucket into the packaging machine and then filling.

Chemical Applications

What you need

Preparation of raw materials according to the formula, add to the base disperser / kneader, powder materials can be put into the disperser for 2-3 times. Through a period of time mixing, the temperature will be raised because of the friction between the materials, to achieve full mixing effect. Start the vacuum system and draw the water from the materials.

Frequently Asked Questions

What is silicone sealant made from?

Silicone sealant, also known as glass cement, is made from polydimethylsiloxane as the primary raw material. It consists of a mixture of a cross-linking agent, filler, plasticizer, coupling agent, and catalyst, which is processed into a paste form.

How does silicone sealant solidify?

Silicone sealant solidifies at room temperature when exposed to moisture in the air. The reaction between the components and water results in the formation of elastic silicone rubber, providing the desired sealing properties.

What are the steps to produce silicone sealant?

The production of silicone sealant involves preparing raw materials, grinding them to achieve fineness, mixing with other ingredients, and then dispersing under vacuum to remove moisture and air before filling into packaging.

What equipment is used in the mixing process?

Key equipment includes a three-roller grinding machine for achieving material fineness, a mixing unit for combining ingredients, and a multifunctional dispersing machine for stirring and high-speed dispersing, all designed for optimal processing.

Why is proper mixer selection essential?

Proper mixer selection is crucial for process optimization, ensuring that materials are mixed effectively and efficiently. Relying on experienced engineers and process technologists helps in choosing the right equipment for specific production needs.

Chemical Industry Contacts

Tom Pruymboom

Sales Director

Area Worldwide

Bart Brouwer

Area Sales Manager

Area Worldwide

Jan Siert Tjeerdsma

Project manager

Technical Specialist

Chemical – Related Articles

Difference between precipitation and crystallization

Precipitation and crystallization are both processes involved in the formation of solid substances from a solution, but they occur under different conditions and result in different outcomes. 1. Precipitation: Precipitation occurs when a solid substance forms from a solution as

Tutorial: How does the Counterflow work?

The Counterflow is a very suitable mixing element for mixing processes of medium viscous liquid products such as paints, polymers and biodegradable plastics where starch is the basic component. In this tutorial we show you how the Counterflow moves the

The Counterflow: from request to solution

Mainly in the chemical industry, the Counterflow mixing element is applied in mixing processes of products such as paint, polymers, biodegradable plastics where starch is the basic component and medium viscous liquids. However, what kind of questions do the customers