Jongia Mixing Technology has initiated numerous mixing processes all over the world using her agitators. In some of these mixing processes, crystallization was a key factor in acquiring the desired final product. The process of crystallization is well-known in the chemical, pharmaceutical, and food industries. In many cases, crystallization is a process that occurs as part of the process requirements for cooling a liquid, enabling crystal formation. Jongia Mixing Technology has supplied crystallization agitators for many projects. In this article, we will highlight a challenging project for Lactose Crystallization in the dairy industry.

In order to prepare lactose for further processing in the pharmaceutical industry, Jongia Mixing Technology was approached by her customer which was in search of an application to separate lactose correctly by means of Crystallization.

The most important preconditions in the crystallization process that Jongia Mixing Technology had to take into account were the following:

- A large working area had to be created in order to optimize crystal growth.

- The product was not allowed to settle on the bottom

- The crystals had to be the correct size, with the best quality.

- The heat dissipation had to match the crystallization process optimally.

Centrally mounted agitators for a optimal crystallization process

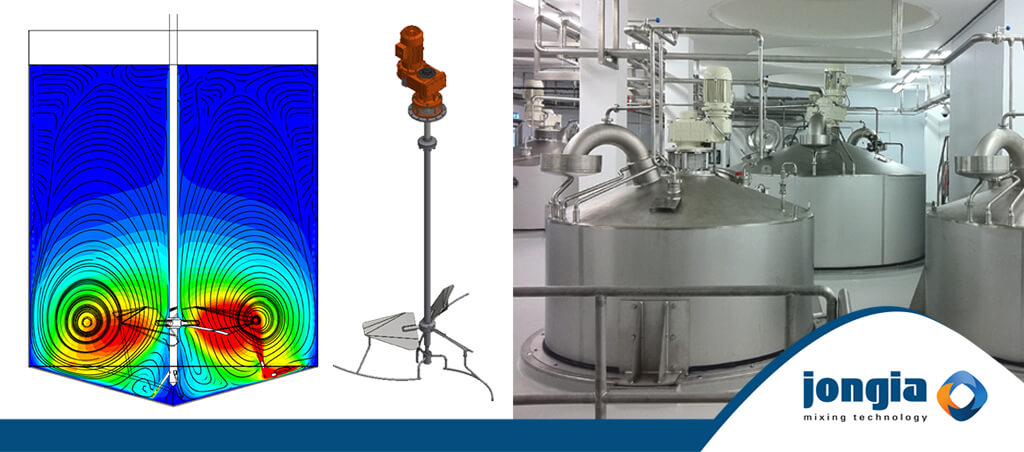

As a large working area optimizes crystal growth, Jongia Mixing Technology chose to advise centrally mounted agitators with large surface hydroprop agitator blades. Normally, the standard version agitator for crystallization consists of a so-called “three-leaf clover”.

However, Jongia Mixing Technology did something “out of the box” and adapted the standard configuration by changing one of the blades to empower the influence on the flow. Due to this change the flow was more active, which not only increased crystal growth, but also made the product sink to the bottom less quickly. Another element that Jongia Mixing Technology added to the agitator setup is the use of a so-called rest stirrer. This rest stirrer is welded to the blades and ensures that no product is left on the bottom. As a result, right up to the last moment the entire tank content is included in the crystallization process.

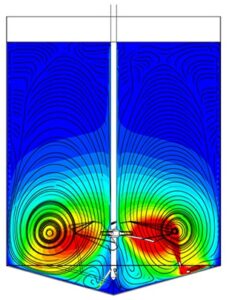

Validation by CFD/computer simulation

In order to prove the modifications suggested by Jongia Mixing Technology would actually lead to a better result and the crystals would have the optimal size, Jongia Mixing Technology used CFD/computer simulation.

Jongia Mixing Technology also went a step further with the computer simulation by projecting the CFD simulation through the (double-walled) tank wall. This provided unique images, which allowed Jongia Mixing Technology to validate the crystallization process with the results from the CFD simulation and optimize the heat dissipation to the stirring process. Eventually these results were sufficiently convincing that the customer decided to purchase the agitators from Jongia Mixing Technology. An outstanding result for both the customer and Jongia Mixing Technology.

Want to know more?

As with all mixing processes, crystallization also needs a specific approach. Jongia Mixing Technology possesses all expertise and experience to give broad advice regarding this product. If you have any questions, please do not hesitate to contact us.

Contact our specialized team for all your questions

Tom Pruymboom

Sales Director

Area Worldwide

Bart Brouwer

Area Sales Manager

Area Worldwide

Technical Questions?

Sijko van der Veen

Application Engineer

Technical Specialist

Fermentation & Bioreactor Mixing Process

Bioreactors and Fermenters are culture systems to produce cells or organisms. They are used in various applications, including basic research and development, and the manufacturing of biopharmaceuticals, food and food additives, chemicals, and other products. A broad range of cell types and organisms can be cultivated in bioreactors and Fermenters, including cells (like mammalian cell lines, insect cells, and stem cells), microorganisms (like bacteria, yeasts, and fungi), as well as plant cells and algae. The words “Bioreactor” and “Fermenter” are basically the same thing.

Tutorial: Batch Crystallization

Jongia Mixing Technology has initiated countless mixing processes all over the world with the help of her agitators. In a number of these mixing processes, crystallization is of great importance to obtain the desired final product. In this tutorial, Area

The introduction of crystallization in the mixing process for the dairy industry

Jongia Mixing Technology has initiated numerous mixing processes all over the world using her agitators. In some of these mixing processes, crystallization was a key factor in acquiring the desired final product. The process of crystallization is well-known in the

Tutorial: How does the Hydroprop work?

To keep starch in suspension, for crystallisation processes and to keep a biogas process in motion, Jongia Mixing Technology has a perfect agitator in its range: The Hydroprop. In this tutorial we want to show you that the Hydroprop is

Jongia supplies agitators for expansion of Mades

Mades is a leading manufacturer of personal care products such as shampoos and lotions. The products are sold all over the world. The company has been growing rapidly for some time, so expansion of the production capacity was badly needed.